Hand Lasted Boots: Overhyped or Underappreciated?

Expert Verified By: George Vlagos, Founder, Oak Street Bootmakers & Sandeep Parihar, Co-Owner, BLKBRD Shoemaker

Practically every brand that sells resoleable footwear calls their product “handmade,” but there are dozens of stages of bootmaking (or shoemaking) that can be performed by hand or by machine.

It’s very easy to miss the words “hand lasted” when reading a description of a boot, but many bootmakers (or shoemakers — we’re just going to keep saying ‘boot’) consider hand lasting to be the most skillful and artistic part of the process.

What does it mean, and why would you pay extra for it? Does “handmade” really mean a better boot? We’ll tell you both sides of the story, and we spoke to five different bootmakers to get you the facts.

Key Takeaways: Hand Lasted vs Machine Lasted Boots

A last is the foot-shaped mold that determines the shape and fit of a boot or shoe. “Lasting” is the part of the process when the leather upper is pulled over the last.

Most brands use multiple machines to last their boots, but some smaller workshops prefer to last by hand.

Hand lasting appears to be better at helping the boot take up the shape of the last, but the average person probably won’t notice. However, it requires a lot of skill and time to hand last a boot, so many guys are happy to pay extra for it.

Why We’re Qualified to Talk Bootmaking

I interviewed multiple bootmakers in multiple countries to give you the best possible information on hand lasting.

First was Chicago’s George Vlagos, the founder of Oak Street Bootmakers and someone who so believes in the superiority of hand lasting that he completely phased out his brand’s machine lasting. For a different perspective, I spoke to David Cook at R.M. Williams, whose factory uses machine lasting.

I also spoke to several makers from small brands that specialize in extra handmade footwear: Sandeep Parihar, the founder of India’s Blkbrd Shoemaker (I visited his operation last year to make this banger video), Bagus Satriow of Indonesia’s Sagara Bootmaker (ditto for this great video), and Mike Pelzer of Adelante Shoes in Guatemala.

Then there’s me, I guess, who actually knows a decent amount about bootmaking. Not just because I’ve visited boot factories and workshops in a dozen countries, but because Mike Pelzer taught me how to hand last boots myself during a rainy week of bootmaking at his workshop.

What Does It Mean to “Last” a Boot or Shoe?

A last is a foot-shaped mold that dictates the shape and fit of a boot. (Again, we’re jus saying “boot” because it’s easier than saying “boot or shoe or loafer.”)

In a world where the machinery and know-how of bootmaking is widespread, a company’s last can be the only part of their brand that’s truly unique. Companies spend months and years developing their lasts and they become closely guarded secrets. Tales of a brand’s employee stealing an employer’s last to start his own company are widespread and considered the greatest act of bootmaker betrayal.

Believe it or not, the job of a last isn’t to precisely mimic the shape of a human foot. Dressier lasts will extend past the end of the foot to terminate in an elegant, almond-shaped toe. Work boot lasts will be roomy to allow for more movement.

People also have different shaped feet, so different lasts work better and worse for different people. Some lasts are designed for more arch support, some for low insteps, and so on.

Lasts also tend to be different in different countries. For example, Vietnam’s Akito Boots told us that Vietnamese feet tend to have shorter toes and higher dorsums. He started his brand to serve the Vietnamese foot shape better.

Culturally, some people (Europeans) like tighter-fitting boots than others (Americans).

Anyway, lasts are a whole thing. Once you have one and you want to make a boot, the pieces of leather are cut out of the hide and sewn together, resembling a two-dimensional boot. Then it’s then pulled over the last — that’s the “lasting” process, and it’s much more complicated than it sounds.

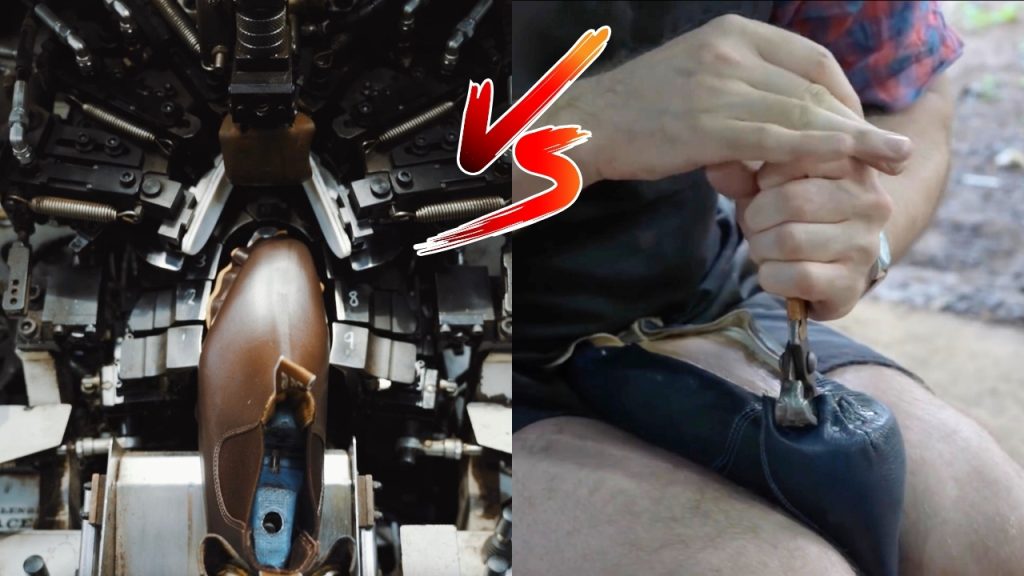

What Machine Lasting Means

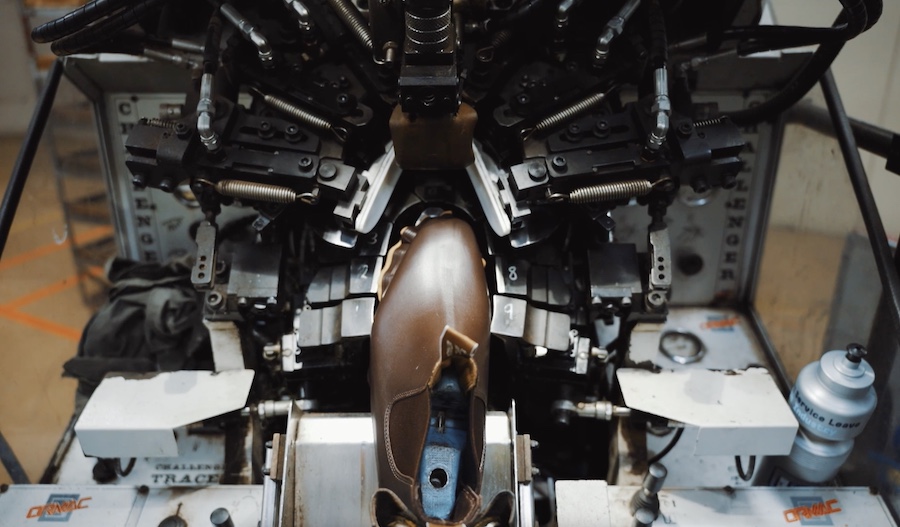

- Machinery grips the leather, pulls it over the last, and secures it to the bottom

- There are typically different machines for lasting the boot’s toe, back, and sides (or “waist”)

- Some brands only use one or two machines; it’s more common to hand last the “waist”

All of the large factories I’ve been to use machines to last their boots because it’s faster and requires less skill.

“When you use a machine for lasting, the machine has its pre-programmed function, grabbing onto the leather and stretching,” says Blkbrd’s Sandeep Parihar.

There are usually two or three machines for lasting the front, back, and sides of the boot. Each part of the operation needs different calculations: the degree of tension applied to the leather, whether or not the leather is heated or cooled (or both), and so on.

It’s important to note that not every machine-lasted brand uses machines for the entire lasting process. For example, when I visited R.M. Williams’ factory in Australia, they told me why they switched to hand lasting for the final part of the operation.

“Because we really need to get a feel for both the upper and the waist, so we just find we can get a much better draft,” says David Cook, the factory’s Head of Footwear and Accessories. “If you were in a factory that makes sneakers that can’t be resoled, you would probably do it all by machine. But because of our last and the particularities of making laceless Chelsea boots, it’s critically important that the leather is properly formed to the last — and that’s really best done by hand.”

There are other elements of the lasting process that we aren’t describing here — once lasted, some places heat the boots so they take up the shape of the last more quickly, others let the leather sit on the last for a few weeks instead, there are pros and cons to that process as well — but let’s focus on why someone might forego machines.

What Hand Lasting Means

- The craftsperson uses hand tools to pull part of the leather over the last before hammering it into place with a nail

- This is performed many times as they move around the perimeter of the last

With hand lasting, the bootmaker has to use a plier-like tool, hammer, nails, and grit to stretch the leather over the last and attach it to the bottom.

The true craft for the craftsmanship comes in with the lasting. The sewing is a skill, but lasting is an art.

Mike Pelzer, Adelante Shoes

It’s not like wrapping a present. The leather is pulled over and over again to get the tension just right. As someone who hand lasted a boot without any experience, I was always wrong when I thought I’d pulled it tight enough.

What Are the Benefits of Hand Lasting?

- The leather takes up the shape of the last more accurately, producing a better fit

- It produces a more consistent product: all boots from the brand and both boots on your feet will fit and wear in the same way

Why last by hand? Obviously, a lot of brands do it because they can’t afford the machinery. Also, a lot of customers seek it out simply because they like a more handmade product. (Nothing wrong with either of those reasons!)

But there are more concrete benefits as to why customers seek out hand lasted footwear.

“With hand-lasting, the craftsman can actually feel the leather conforming to the shape of the last,” says Sandeep. “Whereas the machine stretches the leather irrespective of whether the upper conforms to the shape of the last or not.”

As an organic material, leather isn’t perfectly uniform: hides vary in denseness, softness, stretchiness, and so on. A handlaster’s job is to understand the leather in their hands and to feel how much it should be stretched.

Remember how I said, when I was bootmaking, I never knew if I’d finished pulling the leather over the last or if I had to pull it even tighter? That’s the skill: it takes a lot of experience to be able to “know” the leather in your hand like that.

George Vlagos of Oak Street Bootmakers gives more detail.

“Every piece of leather has a measurable and variable amount of stretch. When a boot is machine lasted, the machine cannot sense that variability or modulate tension accordingly. It applies a fixed pulling force, regardless of the specific characteristics of the leather,” he says.

“With hand lasting, the operator controls the tension in real time, with their own hands, allowing each boot to be pulled to its own optimal stretch point over the last. For example, because the right and left boots are cut from different sections of the hide, even when sourced from the same skin, each will stretch differently. With hand lasting, each can be lasted independently and more precisely. The result is more accurate conformity of the leather to the last, improved fit, and greater consistency across the finished product.”

These boots are a sublime balance of casual and quality, made with rare techniques (like hand lasting) that are highly sought after by enthusiasts.

Look, Most People Probably Won’t Notice the Difference

Hand lasting is really cool and takes a lot of skill: brands are right to charge you more for it.

But would 99 percent of Red Wing Heritage’s customers notice the difference between a machine lasted boot and a hand lasted boot? No.

It’s something you’re more likely to notice if you “just” own a few pairs of boots and wear the hell out of them. But even if you don’t notice it, everyone respects hard won skill. I like to pay for boots that nurture these skills.

Wrapping Up: Why People Pay for Hand Lasting

That might have been an unsatisfying way to answer the big question this article is asking, so here’s a summary of why hand lasting is worth more money.

Hand Lasted Boots Fit Better

This is because the leather better takes up the shape of the last. This means the brand can be more confident that the boot they’re selling will fit just like all their others. It also means the customer can be more confident that they’ll get a boot befitting the brand.

Hand Lasted Boots Do a Better Job of Improving With Wear

This is also the job of the clicker, who selects the right pieces of a hide for each piece of the boot before it’s sewn and lasted.

But to keep things simple: leather boots conform to the shape of the wearer’s foot over time, and hand lasted boots will do so a little better because all the pieces of leather have undergone just the right amount of tension.

Hand Lasting is a Legitimate, Impressive, and Rare Skill

It’s there in the name: this is done by hand, and it’s not as simple as nailing with a hammer. It takes a long time to understand leather and bootmaking well enough to perform this task. I know that from experience!

Bootmakers consider hand lasting the most artful part of the process.

Not everything takes both more time and more skill but hand lasting does, so it’s literally worth more money. Plus, as both Mike Pelzer and Sandeep Parihar told me: bootmakers consider it the most artful part of the process.

It’s good to pay for things that help to preserve rare skills. (Another example of this in bootmaking, by the way, is genuine handsewn moccasin construction!)

Hand Lasting is Traditional and Manual, Which Some People Just Like

“Hand lasting allows us to control the tension better, resulting in a superior fit and durability,” says Bagus Satriow from Sagara Bootmaker. “We do all the processes by hand — as you can see, we don’t have all that big stinking machinery. We enjoy our older production techniques.”

I’m not sure if there’s a word for this concept, but when you wear something that’s extremely handmade, there’s more of the maker in the product. Many craftsmen, cobblers, and customers talk of the bond that they all share through the one boot. You get more of that with something handlasted.