Indonesia’s Most Mysterious Bootmaker: An Interview With Onderhoud

In the world of really, really nice shoes and boots, there is a parallel universe operating in the Indonesian city of Bandung in West Java. A city famous for its creatives and artisans, there’s a thriving community of cordwainers who make boots the really old-fashioned way: I’m talking hand-welting, hand lasting, hand sewn Norwegian welts, the works.

These methods of construction are very old, very laborious, and very highly sought after in the community of boot lovers around the world, especially in the US.

And of the many footwear workshops in this city, there’s an operation that’s one of the smallest and hardest to patronize, with a client list that you can only hope to enter through a lottery a couple of times a year.

So I had to visit Onderhoud and interview the brains of the operation, Rizky Afnan. Here’s why so many Americans are so desperate to wear his footwear, no matter how many he says “no” to.

Why Bandung Attracts Bootmakers

Stridewise (SW): My first question is, why is there such a strong boot-making culture in Bandung? Why are there so many bootmakers here?

Rizky: Indonesia was a Dutch colony until the mid-20th century, so it’s from the colonial times; it’s a part of Dutch heritage.

Further Reading

9 Best Indonesian Boot Brands You Should Know About

The best boots from Indonesian makers and how to buy them. Learn more →

SW: So why did you get into boot-making yourself? What was your journey? Why did you choose this as a career?

Rizky: Onderhoud was born when I was studying industrial engineering at Widyaloka University in Bandung. For a course assignment, I researched micro, small, and medium businesses in Bandung, including the shoemaking hub of Cibaduyut. I began visiting often, saw a business opportunity, and since I’d loved shoes since high school, I started selling them. That continued until I graduated — though only a few of us did graduate!

SW: That’s interesting. I’ve met a fair few bootmakers in the US who started as engineers, it’s not all that uncommon to arrive at bootmaking through an engineering background: the way components fit together and disperse load and so on.

Is it Hard to Find Apprentice Bootmakers?

SW: Many bootmakers in the U.S. tell me that they struggle to find young people to start working in this field, that young people are less interested in working with their hands these days.

Is this a problem in Indonesia as well?

Rizky: It’s the same here. The reason I want my business to stay small is that I try to “reproduce” young craftsmen: teach them to master bootmaking techniques like hand-welting. I’ve brought in many craftsmen who “studied” under me; only a few wind up “graduating.”

Only a few become craftsmen who can really do this. From patterning to cutting, assembling, stitching. It can all be done right here: our craftsmen will learn hand-welting after one or two months of apprenticeship.

What Makes Onderhoud so Successful?

SW: How many boots or shoes can you make in a week?

Rizky: Maybe two or three pairs.

SW: How long is your waitlist right now?

Rizky: Four to six months.

SW: One reason you have such a long wait for your boots is that you like to keep your shop small. But also, of course, there’s so much demand for your boots because you have such a strong reputation — even here in Bandung, where there are lots of very good bootmakers.

What is it about your boots that has earned you such a strong reputation and such a long wait time?

Rizky: Why am I famous? Maybe because I’m a craftsman myself, who does the work himself. So I work every day at that table as a craftsman, not as a brand owner. I really do the work.

Further Reading

Why Are Americans Obsessed With Indonesian Boots? We Visited to Find Out

I went to Bandung, Indonesia, to learn what makes Indonesian-made boots special. Learn more →

Onderhoud’s Popular Boots

SW: These boondockers are so well made, and so hand made. The stitches that run through the midsole are actually angled, they’re all just a little diagonal, so as to emphasize that it’s been done by hand.

It’s one of these many touches where the boots are almost so perfect that it’s impossible to think of a human being making them.

… I actually don’t have a question, I just wanted to point out these remarkable touches that you just never see because the standards here are so incredibly high.

Onderhoud’s Service Boots

SW: Let’s talk about some of the models because I’ve noticed some brands are well-known.

Sagara are well known for their monkey boots. Briselblack are well known for Chelseas. Your brand is best known for its service boots, especially your boondockers (roughout service boots inspired by those worn by World War 2 service members).

How did service boots become such a popular part of the Onderhoud brand?

Rizky: I don’t know why they’re so popular either. With my service boots, there’s actually not much difference from those other brands, like Sagara or Briselblack. What might make it popular is the last: it has its own characteristics which, in the eyes of the customers, are different from other brands.

Further Reading

Meet the Maker of Asia’s Favorite Chelsea Boots: Interview with Briselblack’s Adi

I went to Bandung, Indonesia, to learn what makes Indonesian-made boots special. Learn more →

Onderhoud’s SVC02 Packer Boot

SW: Right now, your packer boot is another style that’s very popular for you. Why do you think that is?

Rizky: First, the pattern is cleaner. It’s more representative of two styles. This boot represents a style that’s both simple and formal, particularly with this high shaft.

Onderhoud’s LVC01 Boondocker Boot

SW: And the LVC01, how would you describe this boot?

Rizky: This is the first boot I made when I was still in Cibaduyut honing my craft. So this is a model that has a lot of history for me, personally. The very first one I sold before the SVC03 was the SVC01.

SW: While we’re talking about your most popular boots, which construction methods are the most popular for your customers?

Rizky: The most common constructions are flat welt, single row, and Veldtschoen. Veldtschoen is similar to double row stitch down, but it’s hand welted.

Rizky’s Most Worn Boots

SW: I wanted to ask you about your most-worn pair of boots.

Rizky: That would be these boondockers, in Horween’s roughout.

This is so beautiful to see the amount of fuzz that you’ve got going on with this roughout. How old are these boots?

Rizky: Maybe three years old.

SW: Do you wear them every day? How long do I have to wear my boondockers to get them looking this nice?

Rizky: No, I don’t wear them every day. I think it would take maybe six months to get them looking like this.

SW: How many boots do you own, and how many do you wear regularly?

Rizky: I own ten to twelve pairs, mostly service boots and packer boots.

Rizky’s Favorite Leather

SW: What’s your favorite leather to wear and to work with?

Rizky: For personal use, my all time favorite is natural Chromexcel (from Chicago’s Horween), in terms of how easy it is to work with and how easy it is to cut. Right now, though, I’m enjoying the traditional harness leather from Wickett & Craig (from Pennsylvania).

The Horsebutt Craze

SW: You were telling me earlier that a huge number of your customers are getting horsebutt leather. What percentage of your boots are horsebutt these days?

Rizky: Almost 70% of my customers are ordering horsebutt leather. Vegetable tanned horsebutt from Maryam Tannery in Italy.

SW: Why does everybody love horsebutt right now, especially in Indonesian boots? I feel like everybody is just doing horsebutt all the time.

Rizky: Maybe because it has some of the cordovan membrane shell part, so horsebutt has some of cordovan’s characteristics, like less creasing and more rolling, but it’s not as expensive as shell cordovan.

Are Indonesian Boots Worth It?

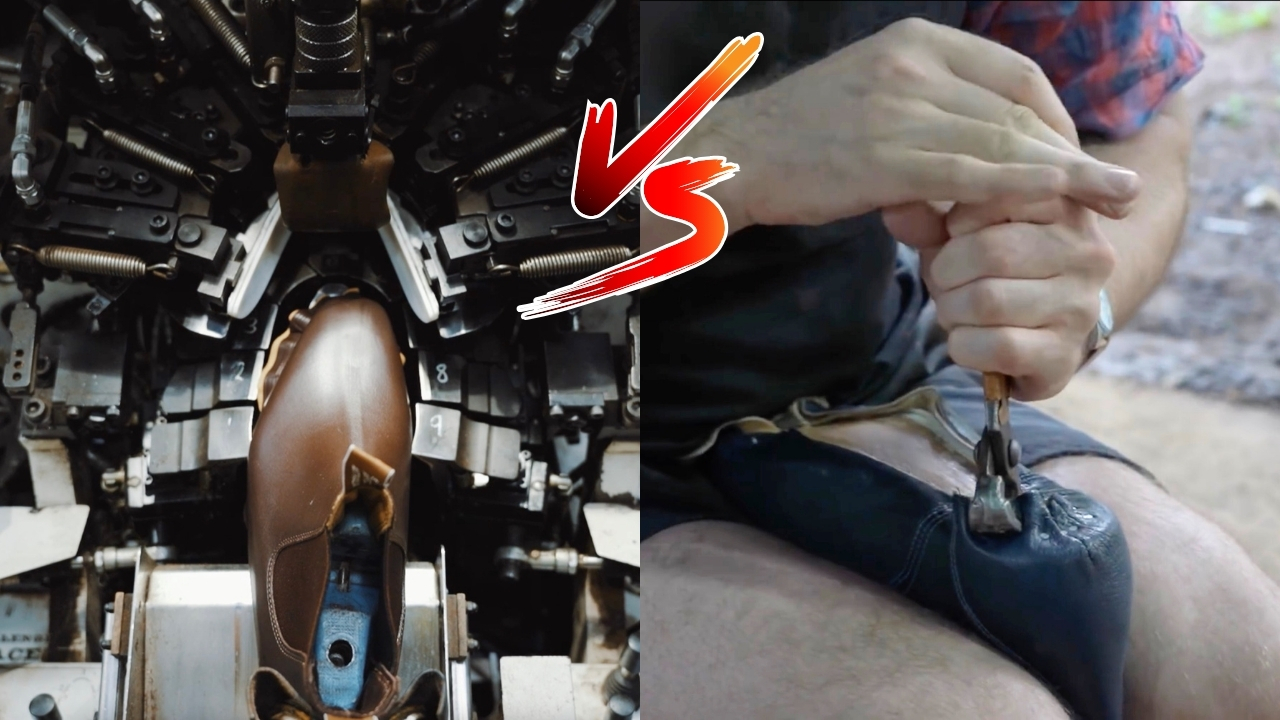

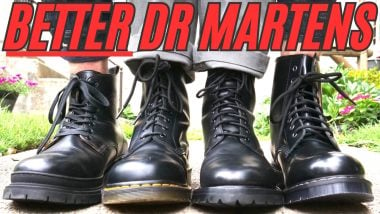

Stridewise (SW): The average American who might not know everything about boots and shoes, he might be wondering what the difference is between a pair of your boots and a pair of boots from, say, Red Wing or Wolverine. How would you answer?

Rizky: My boots are hand-welted as opposed to Goodyear-welted, which is much more laborious, and I believe more durable: instead of the welt being stitched through canvas gemming that’s glued under the insole, I instead hand stitch through a flap of leather cut out of the insole itself. There are fewer failure points in a hand welted boot, which can justify the higher price for some.

To differentiate from other brands, we do slanted seams, and the hand lasting process is superior for quality control because we can disassemble a boot and hand last it again if we find any problems or asymmetries during our quality control.

If we instead used machines to last, like the vast majority of companies that make their boots at scale, the tension on the leather is much higher, and it’s much more difficult to relast or rework a boot.

Further Reading

Hand Lasted Vs Machine Lasted Boots: Does It Matter?

We interview five bootmakers to explain the different ways of lasting boots and what it means for your experience wearing them.

Learn more →

The Future of Onderhoud

SW: Are you happy having a small business with a long wait time for customers, or do you hope to have a bigger operation one day?

Rizky: I have no ambitions for a bigger business. It’s better to have a business that’s small but long-lasting. And to produce new craftsmen with the skills to make hand-welted boots.

SW: The clicking, the cutting, the sewing, the gluing, that’s all done by one craftsman at a time?

Rizky: Yes, I want every craftsman to have a holistic skill in every part of the process.

I have no ambitions for a bigger business. It’s better to have a business that’s small but long-lasting.

Wrapping Up

Onderhoud.handmade — that’s Rizkys’ Instagram handle. If you’re interested in a pair of these boots, you’ll need to be patient: he opens for orders only periodically and he does so with a lottery system.

That wraps up my too-short visit to West Java — a huge terima kasih to the Bandung government for providing logistic and linguistic help as I navigated the city. There are countless places I wish I’d seen, so hopefully I can return to share more of this fascinating bootmaking world.