How Thursday Boot Company Makes “Weatherproof” Suede (10 Steps)

Thursday Boot Company stands out in the industry for a lot of reasons: phenomenal value, shock absorbing insoles, the super versatile dress boot/work boot hybrid. But something that really drew my attention when reviewing Thursday’s Chelsea boots is the astounding Weatherproof Suede.

Suede, as you may know, tends to be fairly thin and stain easily from water and dirt — dainty is the word usually used to describe it. But Thursday has managed to produce a suede that’s not just waterproof, it’s water repellent, hydrophobic — water just bounces off it like it has someplace to be.

So on a recent trip to Leon, Mexico’s leather capital, I decided to stop by Thursday’s headquarters to investigate how exactly they’ve so decisively changed the suede game. Their Supply Chain Manager and resident leather expert Aziz Pereya Mubarqui joined me on a tour of their suede manufacturer Alfamex to explain how.

What is Suede?

As a quick primer, suede tends to be thinner than full grain leather because it’s split down the middle. While most leather has the smooth-ish “skin” one the outside, suede is split so that the exterior has a fuzzy nap — this is the flesh. Note that although it looks a little similar, suede is completely different to roughout, which is made by simply flipping the leather inside out so that the “flesh” side of the full grain leather is on the outside of the boots. While you’re still seeing fuzzy flesh, the leather hasn’t been split, so roughout is thicker and tougher.

While it’s not as tough as roughout (which was a favorite on army service boots in the World Wars), people still like suede because its thin and porous nature makes it soft and breathable, making for a pretty luxurious feel and look. The downside, again, is that it’s fragile.

Here are the 10 steps Thursday takes when the animal skins arrive at the Leon facility to ensure their suede is as tough as can be.

[Learn more: Suede vs Roughout – What’s the Difference?]

1) Split the Hides

Once the hides arrive at the facility — all of Thursday’s leather uses Tier 1 hides from American cattle — the first step is to undertake the process that turns leather into suede: splitting it down the middle with a giant, mechanized blade.

The workers categorize the hides into leather from the belly, which is weaker and therefore repurposed, and from around the animal’s back, which has the strength they’re after . The hide is stronger where the grain is the tightest, and with grazing animals like cattle, the shoulders and back produce the strongest leather.

2) Sort the Hides

Now that they have their suede, they decide which ones will become boots and which will be repurposed or used for other brands. Aziz notes,

We sort the leather in low quality and high quality. Thursday Boot Company only uses high quality suede.

The lower quality ones get discarded or they go to other brands. The high quality ones, of course, are used to make Thursday boots.

3) Shave the Hides

Although suede is known for its hairiness, we’re not talking about Gillette razors here. This is the part of the process where the suede is shaved down — thinned once more – to attain a relatively uniform thickness that’ll make it workable and consistent for the boots. Naturally, suede is a tad thinner than full grain leather: the final thickness that’s desired is between 1.6 and 1.8 millimeters.

So what’s next once the hides are split, sorted, adjusted for thinness, and we know which ones we want to use?

[See more from our Mexico trip: Why Lefarc Is Mexico’s Most Sustainable Tannery]

4) Retanning (or, The Weatherproofing Begins)

“Now we go to another facility where they put the suede in drums,” says Aziz. That facility is Alfamex, a renowned producer of many kinds of leather — but their reputation is for suede.

Here’s where the first crucial step of Weatherproofing takes place: the suede is placed into giant drums that tumble it with a variety of greases, oils, and waxes that increase the moistness and the water resistance. More complex waterproofing takes place later, but remember that oil separates in water and rain bounces of waxed jackets — these are traditional and surprisingly effective ways of waterproofing.

5) Drying the Hides

As you can see in the previous section, the hides appear soaking wet after the retanning, and drying them is a long, elaborate process unto itself.

“First of all we go to the draining machine where we extract between fifty and sixty percent of the water that we add in the drum,” Aziz explains. “Then we go to the vacuum drying machine which extracts more of the water with a vacuum and heat system. The final process is the air drying process, which is simple: you air dry like you would your clothes!”

6) Buffing the Hide

Now that the suede is dry, there are four more stages in the surprisingly elaborate production process.

Next up is buffing. Once it’s dry, a quick pass will show that the suede still has some inconsistencies: it’s uneven and not super smooth. So at this stage, the workers run the hides through the machines you see above that produce an effect not unlike sandpaper: they’re buffed and smoothed out to become fuzzier and, well, more aesthetically pleasing.

7) Color Adjustment

When the hides get to Alfamex, they do get dyed to an extent. But here is where the color is fine tuned to match the exacting standards of the quality control team.

“Right now we have to adjust (the color) with some aniline, and then the machine applies it to the suede to get the color that we want for our boots,” says Aziz.

Thursday has a scale that shows a minimum and maximum variation in color that they allow for the leather to be usable and you can see in the image above that Alfamex uses a huge, elaborate machine that helps fine tune the color to within couple of percentage points. Now it’s uniform in appearance and customers get the color they expect from the brand.

[Shop Thursday’s Chelsea boots here!]

8) Apply Silicone Waterproofing

“This is the last step that seals the suede to keep water from entering it,” says Aziz.

Silicone is relatively common in leather conditioners because it’s quite hydrophobic: when applied correctly (and there’s a lot of complicated physics that takes place here), water droplets ball up and roll off of it, as you can see in the video above.

Then after that you the silicone is added…

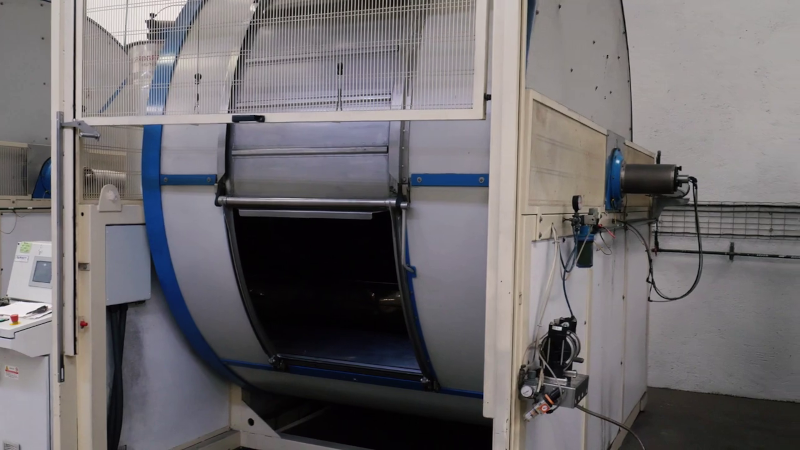

9) The Tumbling

A step that many don’t anticipate when they think about creating leather is tumbling: before it’s ready to be made into boots, most leathers are tumbled in a machine that’s a little like a clothes dryer. Tumbling it around and around softens the leather and makes it more comfortable for wearing. How long does it take? In this instance, five to twelve hours.

10) Quality Control

A lot has happened to this leather since we got here, but we can’t just assume that it’s perfect. Before it’s sent away to become boots, we need a human touch: this is where the quality control team steps in to examine the suede with a fine toothed comb to ensure consistency, thickness, color, and durability.

[Learn More About: How To Clean Suede Boots]

Wrapping Up

Feel like a suede expert yet? I know I learned a ton on my trip to Mexico and I’m delighted to have glimpsed this look into the incredibly elaborate world of bootmaking — even before I saw any eyelets and laces! I’ll never look at suede the same way again; its production is extremely technical and even moreso when it’s the Weatherproof Suede from Thursday Boot Company.

Join the Discussion