Inside (Literally) Thursday Boots’ Premium “Black Label” Collection

Thursday Boot Company soared to the top of the boot industry by making Goodyear welted boots for under $200, but what happens when they decide to pull out all the stops and make boots for the world’s most discerning, money-is-no-object boot fans?

You get their ambitious new Black Label Collection, a batch of boots made to unreasonably high standards. Leathers from tanneries like Shinki and Maryam, double row stitchdown construction, all leather internal components (even the shank), and all the bells and whistles that the high end boot nerds have been missing from the brand.

Intrigued, I took the C train to their headquarters in Manhattan to meet up with CEO and co-founder Nolan Walsh and ask him how and why he developed this new line — and got a sneak peek at future Black Label releases while I was there.

Overview: What’s Thursday’s Black Label Collection?

“What defines the Black Label collection is that we’re using super high-end leathers from the most renowned tanneries in the world,” says Nolan. “All the components are the highest quality: all leather internal components, a fully gusseted tongue, double row stitchdown construction, and they’re made in super small batches. I’m talking five unit batches by our most senior artisans, and limited edition by nature.”

How is that different to their regular boots? Those boots, like their bestselling Captain, are made with an emphasis on comfort, versatility, and value, while the Black Label is made for customers looking for the most exclusive leathers and construction methods on the market.

Thursday wouldn’t mention the brands they’re trying to compete with when I interviewed them (#corporateniceties) but the Black Label’s first release, the incredibly meaty Challenger, is clearly, um, challenging Pacific Northwest giants like Nicks Handmade Boots and their Urban Logger I reviewed.

Rare leathers from world-class tanneries, a chunky sole, stacked leather Woodsman heel, and laborious stitchdown construction for under $400.

Thursday Challenger vs. Captain: Addressing the Boot Nerds

Thursday’s boots are super legit, but there’s a difference between a $200 boot and an $800 boot. The brand is coming out with several models for the Black Label Collection and they’ll all have different features (more on that later) but here are some of the differences between the Challenger and the Captain.

A More Chunky, Logger-Style Look

The Captain, like most of Thursday’s boots, has been painstakingly designed to fit with as many modern wardrobes and styles as possible. That means not going with the old fashioned mining boot look, opting instead for a sleeker, lower profile design that’s more versatile and can dress up more easily (if you’re picking a smart leather).

The Challenger is casual, firmly and proudly. It’s got a huge, 22-millimeter stacked leather heel, a wide toe, an authentic toecap, shiny eyelets, and a build that screams “beat the hell out of me.” There’s nothing urban or sleek about these.

All Leather Internal Components

Boot hobbyists tend to want thicker leather uppers, they prefer the toebox and heel counter to be stiffened with natural leather over the standard plastic-impregnated fabric called celastic, they often prefer leather shanks, and, well, they just like more leather. All of those boxes have been ticked for the Challenger.

“When thinking about the Challenger, we really are taking into consideration the comments from the people who love the brand, but the Captain’s not for them,” says Nolan. “How do we get the boot that they absolutely love so they can be on ‘Team Thursday’?”

One way Thursday succeeded is by recognizing the average guy prefers an easier break in and better shock absorption than you get with traditionally made work boots, so they swapped the old fashioned leather insole for shock absorbing poron foam. But there’s a (vocal) contingent of boot fans who prefer more layers of leather underfoot instead, because it does a better job of conforming to the shape of the foot over time.

“That’s one way of putting it,” Nolan conceded. “Some guys prefer that over the better shock absorption. You know, it’s just different preferences.”

That’s just one of the criticisms that the Black Label Collection is addressing by using all leather internal components and ditching the celastic and poron.

Looking for other ways to improve comfort, Nolan added a layer of vachetta leather underfoot: a luxury, vegetable tanned leather often used in high-end bags instead of the classic stiff and thick leather insole. (But there are multiple layers of that leather as well, don’t worry.)

“The tannage was a bag leather, and I really think it’s much more comfortable than just going straight to your usual stiff veg tan leather,” Nolan says.

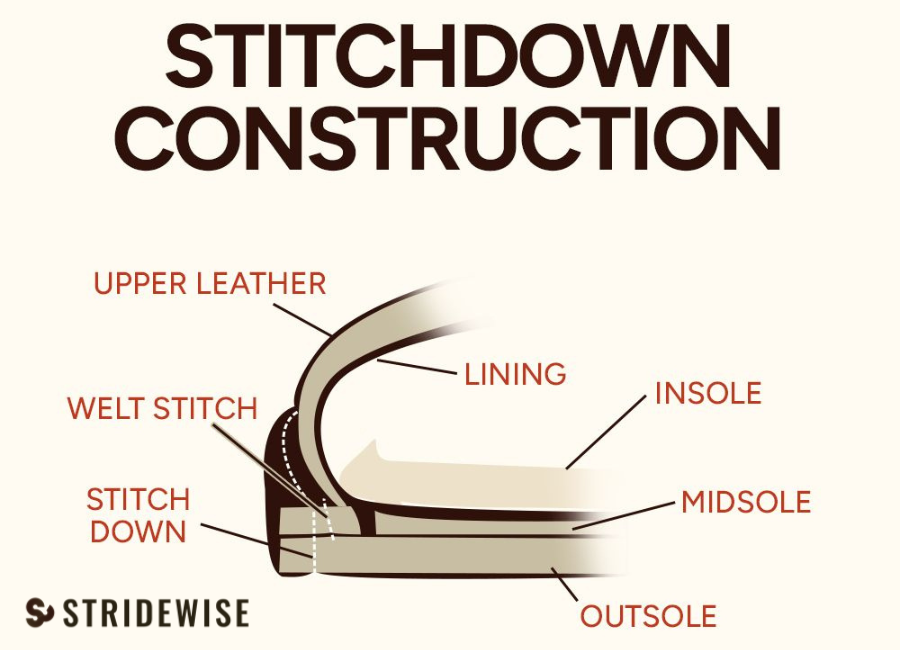

Stitchdown Construction

Most resoleable boots are made with a Goodyear welt, a method invented in the 1860s that replaced the super time-intensive hand welting process with a machine that completes the job in under a minute.

But there are other ways to make a resoleable, hardwearing boot, and a lot of boot guys prefer stitchdown construction. One can make the case that it’s more waterproof and durable, and while you’re kind of splitting hairs when comparing those elements, there’s no denying that the way higher end brands perform stitchdown construction is more laborious and skillful than the Goodyear welt machine.

Boot nerds gravitate toward that more artistic side of the craft, and the Black Label Collection does too.

“I think it’s a very hard argument to make that one is better than the other from a technical standpoint,” says Nolan. “But I really like the lower profile look you get with it on a boot like this. You get a very clean toe look because the leather’s folded out and stitched through the midsole.”

A Gusseted Tongue

Boots that are more geared toward outdoor use often have gusseted tongues: the tongue is stitched to the eyelet panel so that no water or muck can make its way through that crack onto your socks.

It’s more work (and therefore more expensive, duh) to make, it’s not really necessary for the average city boot, and because of their eye toward keeping the cost down most of Thursday’s boots don’t gusset the tongue .

Not so with the Challenger: not only is the tongue gusseted but, like I said, there are arguments that stitchdown construction is more waterproof than Thursday’s usual Goodyear welt builds as well. (We don’t lean hard on that opinion, but for the guys that make that a complaint, it’s been answered.)

Rare Leathers

Thursday’s regular boot leathers come from all over but most are from Lefarc, a super sustainable tannery I visited a couple of years ago to learn how to make boot leather. (I then made boots with it in Guatemala, but I digress.)

Lefarc’s leathers are very good, but there are guys who prefer more old fashioned ways of making leather like 100 percent vegetable tannage, and guys who prefer even stiffer and thicker leather like horsebutt and cordovan.

These sorts of customers are rare, so it didn’t make sense for Thursday to cater to them when their priority was growing the company — but now they’ve got bandwidth to appeal to them, too.

“The Black Label boots aren’t made with leather that’s made at a high volume,” says Nolan. “Our plan is to just do some of that special upper echelon stuff for the true boot geeks such as ourselves, and have a lot of fun with it.”

We’re talking ultra rare Shinki Cordovan, C.F. Stead’s beloved Rambler Leather, Whiskey Predator from Chicago’s Horween, and two more vegetable tanned horse leathers from Italy’s Maryam: Toscanello TPR and the patina powerhouse Teacore Horse Rump, which sold out the day of release. (People love “teacore” leather because the black finish wears away to reveal the leather underneath — sort of like earning your jean fades.)

The Price

We won’t pretend that a big part of Thursday’s success is managing to keep the price under $200 for most of their boots.

The Challenger boots cost $349 to $369 and the Cordovan one is $549 — these are all unbelievably good prices for the materials and build.

If you know anything about the kind of boot I’ve been describing, you’d assume it was well over $600, even if it were made in Mexico. (Compare with Unmarked, which is less substantial, made in Mexico, and costs about $500.)

Rare leathers from world-class tanneries, a chunky sole, stacked leather Woodsman heel, and laborious stitchdown construction for under $400.

Thursday’s Evergreen Challenger Boots

More interested in the fancy build than the fancy leathers? Good news: there’s an Evergreen line made with new Lefarc leathers for $289.

“This one’s called Grand Canyon,” says Nolan, pointing at the boot represented by the jpeg two paragraphs north of these words on your screen. “It’s kind of a mixed between the Arizona Adobe and Burnt Copper, two leathers really popular with Thursday nerds like me. It’s a nice, oil tanned leather, really rich color, and wears really well.”

He expects most of the Black Label leathers to be replaced every season.

“The other Evergreen leather out right now we’re calling Golden Brown, which is a hot stuffed leather similar to Chromexcel that wears really well, too. The main difference is the batch size of the product we’re making.”

Other Black Label Collection Releases

Nolan showed me a few of the then-forthcoming releases in the Black Label Collection: a whole-cut Chelsea boot (which is now out), a boot similar to the Challenger but with a lower heel, and a stitchdown moc toe. I saw one moc toe made of green cordovan and another made of suede embossed to look just like denim, but which ones are going to market I’m not sure.

But the Chelsea, which they’ve called The Journeyman, is firing on all cylinders. Practically every Chelsea on the market is stitched from a good three or four pieces of leather with a seam underneath the elastic goring. This pattern, fashioned from a single piece of leather, is much harder to make and many find it more comfortable and aesthetically superior.

“The Chelsea has the same internal components and aside from being whole cut, I think the last is super comfortable,” Nolan says. “It’s going to be the first boot featuring our new Knight outsole, which we’re really proud of. The traction on this is incredible, really great abrasion resistance.”

Wrapping Up

This represents a significant shift for Thursday as they enter into the high-end casual boot market.

I saw a lot of other boots on my visit that I’m meant to keep quiet about, but I can tell you they’re innovating just as much for the $200 boot buyers as well.

Interesting article and gets me really excited for the Black Labels. Have you got information if the Wholecut Chelseas will be released in Shell Cordovan?

That boot IS out in cordovan, but they couldn’t get it whole cut. Still, it’s a shinki Chelsea!