Is Cordovan Worth It? A Complete Guide to the Fanciest Shoe Leather

Many guys love fine leather footwear and will engage with it as a hobby for years before learning about the existence of shell cordovan. Most brands won’t touch the stuff, and those that do typically start their prices for a pair of shell shoes at $700.

On a recent trip to Europe, I knew I had to visit the Spanish island of Mallorca to explore Carmina Shoemaker, a company that has been running under one name or another since 1866. That’s before the Goodyear welt was even invented!

Known for their Chelsea boots and their cordovan shoes, one of the videos I filmed with them is all about cordovan, a subject I’ve never explored before on my channel. Ioana Dinu, Carmina’s business development manager, answers that complex question in the clip below: “Why is this type of leather so darn expensive?”

[Shop Carmina’s Shell Cordovan Collection HERE]

Named in part for the city of Cordoba, Spain, where cordoban was first produced in the seventh century by the Visigoths, shell cordovan is an increasingly coveted commodity in men’s footwear.

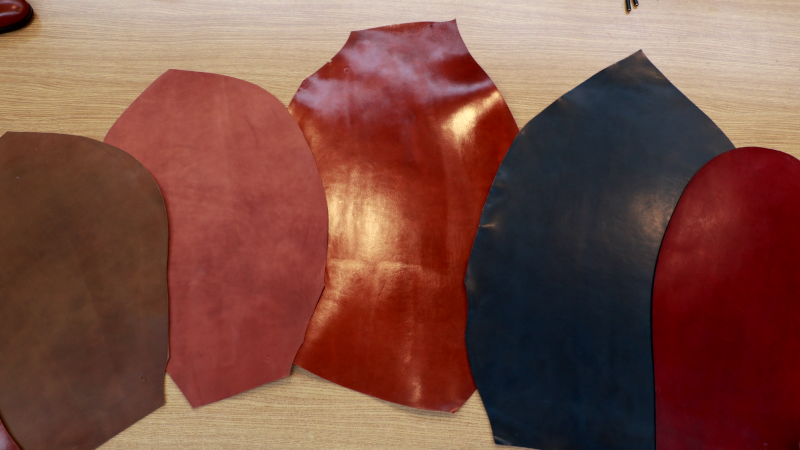

Though it’s also used to craft wallets and watch bands, cordovan is predominantly sourced to craft high-end dress shoes and boots.

And by high-end, I mean high-end. The raw material clocks in around $100 per square foot, and Viberg’s classic service boot in shell cordovan will run you over $1,700. Here’s how it’s made by one of the world’s greatest producers of the stuff: Horween Leather Company in Chicago.

What Makes Cordovan So Different?

Not only is shell cordovan an indisputably good-looking leather, but it’s one that only gets better-looking with time. Shell cordovan is a self-polishing material, which means that you don’t have to do much at all for it to develop a beautiful sheen: you just brush it vigorously, and the heat will enliven the oils and waxes imbued in the material, allowing its already impressive appearance to take on an all-new luster.

Did I mention it’s remarkably durable? Well, it is. Not only does it look great, but shell cordovan doesn’t crease the way basically every other leather does. That’s because over time, it ripples rather than creases, and creases are what lead to cracks.

It sounds strange, but the ripples are subtle and really add to the beauty of the patina. Provided the soles are changed out periodically, a pair of shell cordovan shoes can last more or less indefinitely.

Granted, there are plenty of finely crafted, high-end materials out there that don’t cost a month’s rent. So what makes cordovan any different? It goes straight to the source…

[Too pricy? See these 11 ways to save money on boots!]

Where Cordovan Really Comes From

To start, shell cordovan is made from horse hide, specifically the flat muscle (or shell, hence the name) from the rump of the horse. You read that right: this leather is made from horse ass.

“Shell cordovan is a premium horse leather. It comes from the rear side of the horse. It’s connective tissue. It’s a membrane. That’s the beauty of it and what makes it so unique. And I suppose its limited availability makes it very, very expensive,” Ioana says.

Each hide yields two ovals of genuine, quality material, which isn’t very much to begin with. And, as most of the world no longer raises horses as part of the food industry, tanneries have limitations on the number of suitable hides available.

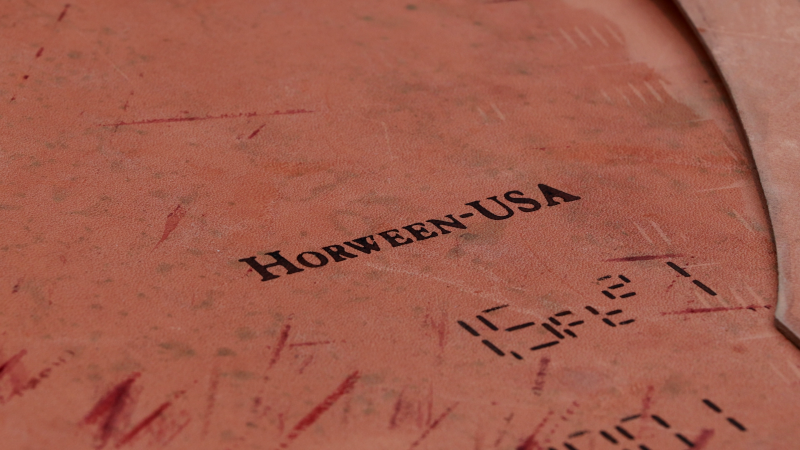

And merely procuring the necessary hides isn’t even the half of it. Processing the raw material into quality leather is a whole other beast. At Horween, the tanning process takes a minimum of six months: hides are vegetable-tanned for at least 60 days, then hot-stuffed and hand-cured, shaved, and dyed by skilled artisans.

The time, money, and skill needed for such a process help make for a spectacularly narrow playing field. Due to the length and complexity of the process, only a few tanneries on the planet bother to produce cordovan these days. Basically, you’ve got Horween in Chicago, Shinki in Japan, and a handful of much smaller tanneries in Italy and the UK.

So there you have it: short supply; high demand —cue cash register sound effects.

[Related: The 7 Best Cordovan Boots on Earth]

Why Horween Is Still the King of Cordovan

According to Ioana, “with its unique characteristics, it’s a very smooth, luxurious leather, its history, as in how it’s been tanned in the Horween tanning factory, it’s also important. It normally takes around 6 months for the shell to develop this color.”

Chicago’s Horween Leather is the world’s number one producer of shell cordovan today, as well as the only one in all of North America. And they’ve had a lot of practice. The company has been making shell cordovan since 1905 — in fact, it was Horween’s original product, and today, they use the same process, though they remain tight-lipped about the details.

One of Horween’s specialties is hot-stuffing, where a proprietary blend of greases, waxes, and oils is pounded into the leather in giant, steam-heated wooden drums. Hot-stuffing is the part of the retanning process responsible for the tactile qualities we love (the look, smell, and feel) and has the bonus of keeping the leather from drying out for a long, long time, even if completely neglected.

Those shell cordovan Viberg Service boots I mentioned earlier? Made with Horween shell cordovan, and usually sold out while still in preorder despite their $1,700+ price tag.

[Read my interview with Horween Leather Company here!]

How to style Shell Cordovan

The last benefit of cordovan, especially if you want a dressier boot, is that it has a much more lustrous shine to it than other leathers.

“It doesn’t need shining that often,” Ioana tells me. “It’s self-shining on its own, you can make it look formal or informal based on its style, based on the outsole, and details. It’s super versatile. I know some people prefer to use it in more casual scenarios.”

A lot of guys, myself included, forget this versatility. Because of cordovan’s price and how the market developed, it’s easy to think of it as primarily a dress shoe material.

But Ioana told me that at Carmina,” customers really prefer our boots, they prefer the casual styles in cordovan. But also we do loafers, and whole cuts, which are more formal.”

This is just the opposite of what I expected.

But looking into it, more popular cordovan styles from other companies fit this mold.

You’ll find shell cordovan used on chunkier boots with a storm welt, chunky lug, and moc toe, like Grant Stone’s Brass Boot. So while it’s very expensive shiny leather that’s often seen on dress shoes, it’s also perfect as an old-timey, durable, water-resistant leather that could work well for environments that would destroy a cheaper shoe.

Further Reading

The 5 Best Japanese Boot Brands

We’ve spent an inordinate amount of time and effort finding the best and most interesting boots out there. Learn more →

Popular Shell Cordovan Footwear

Loafers are very common in shell, they are also some of the lowest priced models: Carmina’s are just under $700.

Alden is famous for its cordovan shoes. There’s a crazy collector’s market because it’s just so incredibly difficult to find their rare colors like Ravello, whiskey, and cigar. Not only do they produce the popular Indy in cordovan, but their classic loafer is very popular.

Crockett and Jones make excellent Shell footwear as well, and they are much easier to buy than Alden. You can just pop on to their website and buy a pair of boots for about $900, vs waiting for years to get a pair of Alden.

New companies like Grant Stone have been making limited releases of cordovan, like their Edward Boot in Maduro shell and honey-glazed Shell for a relatively low price of $695. A pair of Grant Stone loafers will set you back 674 bucks, but they’re only occasionally available.

Indonesian bootmakers are well-known for making lovely cordovan boots at a much lower price; I’ve just picked up a pair from Midas Bootmaker myself.

Your best bet to find a cost-effective cordovan is to check out Grant Stone or Indonesian bootmakers, who can sell it for less because they find ways to lower the cost of labor.

Who should buy shell cordovan leather?

- People who are transitioning into higher-end footwear

- Guys who want classy, durable leather for their boots and shoes

- Anyone who wants long-lasting leather that looks better as it ages.

Who shouldn’t buy shell cordovan leather?

- Guys just getting into wearing nice boots, this probably isn’t going to be your first pair of Goodyear Welted boots or dress shoes.

- Anyone who likes more rugged-looking boots, or boots with dull leather.

- You don’t want an ostentatious boot, the shininess really stands out

Shell Cordovan: Worth the Sticker Shock?

Even for the world of

It’s no exaggeration to say that they’ll last you a lifetime — so if you’re looking to buy one pair of high-quality shoes for literally the rest of your life, look no further than shell cordovan.

Ok, thanks again to Carmina for letting me film in their factory and to Juana for answering my questions about this really interesting leather.

Images via JD Sassone on Instagram. Read his op-ed: Why Alden Is By Far My Favorite Shoe Company.

Mel what brand is that beautiful red oxford shoe?

That’s Carmina’s wholecut!