Goodyear Welt vs Stitchdown Construction Pros & Cons

When it comes to durable footwear, you’ll hear plenty of buzzwords about construction methods. But if your priorities are durability, water resistance, and ease of resoling, two techniques dominate the conversation: Goodyear welting and stitchdown construction. The Goodyear welt is by far the most common, while stitchdown is less widespread — but no less important.

So which is better? And in what ways?

To answer those questions, I visited Dave of Old Speed Manufacturing, a Pennsylvania bootmaker whose brand focuses on stitchdown construction. As a cobbler, he also spends much of his time repairing Goodyear welted boots — giving him rare firsthand insight into the strengths and weaknesses of both methods. I also chatted with boot collector Jake from Almost Vintage Style to provide his perspective from a guy who’s worn both constructions.

Key Takeaways: Goodyear Welt vs Stitchdown Construction

- Both are durable and repairable, but it’s easier to find a cobbler to repair and resole Goodyear welted.

- You might have to send stitchdown boots to the original manufacture.

- Both are comfortable, but construction is only one aspect of comfort

- Stitchdown is more water-resistant.

- There are exceptions to all of these rules.

What Is a Goodyear Welt?

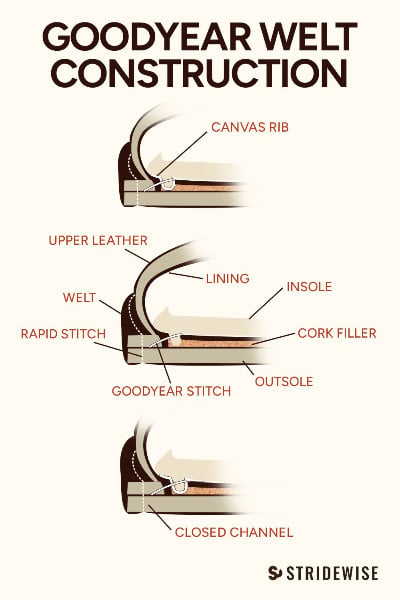

- A Goodyear welt is the actual welt or piece of leather that connects the insole to the outsole

- Durable and resoleable throughout its life

- It has a good balance between durability and flexibility

So what exactly is Goodyear welting?

“In short, it’s a construction method where the upper is stitched to a leather strip called a welt, which is attached to a rib on the insole,” explains Dave. “That welt provides a secure anchor for the outsole — so when the sole wears out, you can peel it off and glue on a new one without disturbing the upper.”

This makes resoles straightforward and extends the life of the boot. Even the welt itself can be replaced if needed. High-quality boots usually use a leather welt, while cheaper ones often use synthetic materials, which makes resoling trickier — but still possible.

Further Reading

Why Hand-Welted Boots Are Better Than Goodyear Welted

Jake breaks down why he likes hand-welted boots more than Goodyear-welted. Learn more →

What Is Stitchdown Construction?

- The bootmaker stitches the upper to the midsole/outsole without a welt

- The upper leather attaches to the midsole

- Commonly found serious Pacasifc Northwest work boots and brands like Clarks and Jim Green

So what about stitchdown?

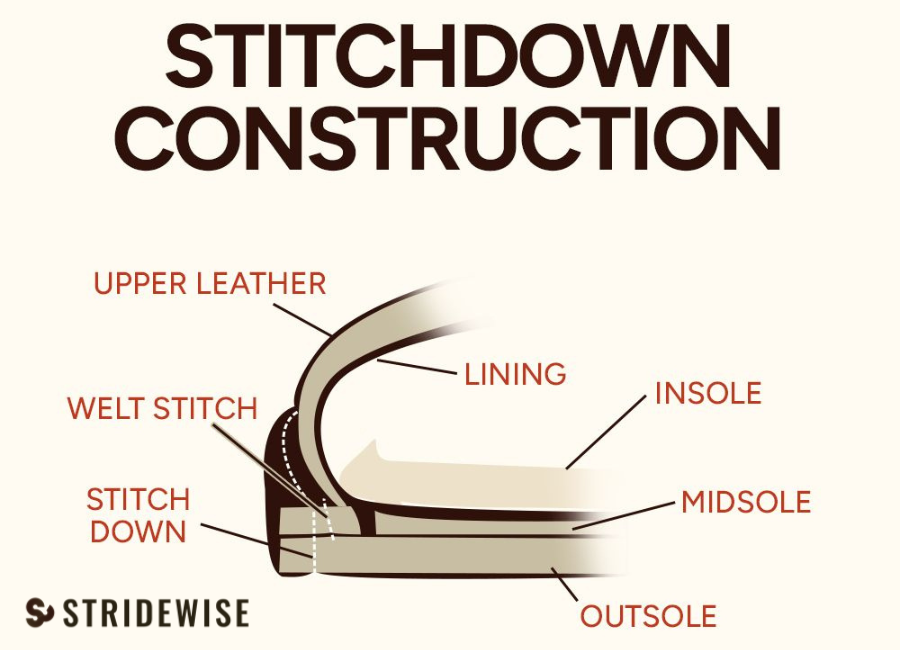

“Like Goodyear welting, the upper is pulled over the last — but instead of being tucked under, the leather is flanged outward, laid flat against the midsole, and then stitched down through both layers,” says Dave. “That stitching seals everything together and gives the boot its distinctive look.”

It’s usually visible because the upper spreads out and flattens onto the midsole, with the stitching running through it. That’s the easiest way to spot stitchdown construction compared to a Goodyear welt, where the upper leather tucks underneath instead.

Are Stitchdown Boots Better than Goodyear Welted Boots?

A lot of guys associate stitchdown boots with higher quality, but that’s not necessarily the case. Dave likes stitchdown because they’re easy to make and look good.

“The first reason is that you can do stitchdown by hand with $20 worth of tools if you have the patience,” explains Dave. “So it’s a great way to get into boot making.”

Essentially, it’s a lot easier to do by hand than, say, hand-welting, where you have to carve a channel, and then you have to poke a bunch of holes, and you have to put the needle through and come exactly out of the right spot.

“Structurally, stitchdown is just as sound as a Goodyear welt,” he adds. “Boots will last just as long, and while they might not take quite as many resoles over their lifetime, the key point is the same: the upper, midsole, and outsole are all mechanically fastened with stitches.”

Both are easily resoleable. There’s also the style factor.

“The second thing, I love the way stitchdown boots look, and I think a lot of people do,” Dave explains. “Maybe it’s the way the construction emphasizes the bottom of the last, or if it’s the tidy appearance of the stitches. It’s just really nice and professional-looking.”

Stitchdown has a distinctive look that sets it apart from the more common Goodyear welted boots you’ll see from brands like Red Wing or Alden. It’s unique, noticeable, and in some ways shows off the craftsmanship even more clearly.

Stitchdown is a Sign of Quality

“Another reason that stitchdown construction is a quality indicator is that it requires the use of thick leather,” says Dave. “It cannot be done with thin, cheap leather. Therefore, when you buy a pair with stitchdown construction, you know that the upper is made of high-quality leather and will last a very long time.”

When the shoes need to be resoled, the upper will still be in good shape. In contrast, there are many Goodyear welted shoes and boots where the welt will be the last thing to fail because the upper is so cheaply made.

Can Brands Fake a Goodyear Welt?

By contrast, Goodyear welts can be faked.

“Some shoes are built with a Blake rapid stitch or even just a strip of rubber or plastic to mimic the look of a welt,” says Dave. “At first glance, they appear Goodyear welted, but in reality, they’re not — making stitchdown an honest, durable, and stylish alternative.”

A lot of brands make big money selling boots that look Goodyear welted, often highlighting how easily they can be resoled — sometimes “infinity times” if you’re willing to replace the welt.

Stitchdown vs Goodyear Welt: Durability

- Durability depends more on more factors than simply stitchdown vs. Goodyear Welt

- If you do not need serious work boots for your job, either one should be durable enough for you

- Stitchdown or hand-welted work boots (like White’s) are more durable, so if you need ultimate durability, go that route

“I’ve opened up many boots from brands for resoling where the lasting board is cracked, and the gemming, the canvas rib that holds the welt, has completely separated and is just floating around,” says Dave. “This allows cork from inside the shoe to get into the footbed area and move around, which changes the shoe’s width.”

This is a good point; with Goodyear welted boots, more parts can come unstuck, and more material can move around inside. A better argument could be made for stitchdown versus hand-welted construction, which doesn’t use gemming, but that’s too complicated.

On the other hand, just being “stitchdown” doesn’t mean a boot is more durable.

“Companies often say that stitchdown construction makes for more durable boots, but this is not always the case,” Jake says. “Desert boots like the famous Clark’s desert boot have stitchdown construction. But these boots and their crepe rubber soles are far from the most durable boots.”

[Learn More: Pros and Cons of crepe soles?]

Further Reading

The Best Boots for Men

Looking for a durable, resoleable boot? We’ve put together the ultimate list to save you money and time. Check out how →

Goodyear Welt vs Stitchdown: Resole-ability

- Goodyear-welted boots and shoes are quite simple to resole for most cobblers and shoe repair shops.

- Stitchdown construction is much more difficult to resole

Many brands make big money selling boots that look Goodyear welted, often promoting the idea that they can be resoled “infinity times” if the welt is replaced. The main critique of stitchdown is that it’s harder to resole and harder to find a cobbler willing to do it.

“That’s a fair point, most cobblers see it as extra work, says Dave. “In practice, though, resoling stitchdown is straightforward. The outsole is removed, then a new one is glued and stitched back on, ideally through the original stitch holes.”

As long as those holes are reused, the upper and midsole aren’t damaged, and the boots can last a very long time, comparable to Goodyear welted boots.

That said, there are limits.

“You can’t run a machine through the same holes endlessly without eventually weakening the leather, explains Dave. “After a few resoles, you may need to accept a less-than-perfect finish, have the boots relasted, or even convert them to a hand-welt or Goodyear-welt construction.”

Goodyear Welt vs Stitchdown: Comfort

- Goodyear welt boots will generally be more comfortable out of the box

- Stitchdown boots will often offer greater support for your feet over long periods of time

What about comfort?

“All things being equal — same leather, same midsole, same insole — there’s very little difference between Goodyear welt and stitchdown,” says Dave. “The main distinction is that Goodyear-welted boots often have more space to pack in cork underfoot.”

That can make them feel softer out of the box, but cork shifts, crumbles, and needs to be replaced during resoles anyway. After a few resoles, both methods feel comparable.

“Some stitchdown boots don’t use cork, though many do,” adds Dave. “The layer is usually thinner than in a Goodyear welt, but it’s still there.”

On the flip side, the cavity in a Goodyear welt can also be used to hide foam or other cheap fillers, something boot purists dislike. They’d rather see more leather underfoot, even if it means a stiffer break-in. Others prefer the way cork molds to the foot and manages moisture.

Ultimately, comfort comes down less to welt type and more to the details: the thickness and flexibility of the midsole, the outsole material, and the break-in. Stitchdown boots, often built with thicker leathers, can feel tougher at first, but that has more to do with design choices than the construction method itself.

Goodyear Welt vs Stitchdown: Water Resistance

- Both have comparable water resistance

- The type of leather and how the upper is glued to the midsole matters more than if it’s Goodyear welted or stitchdown

The reduction in your ability to resole is the most valid point against stitchdown construction. There are many other points people raise against it that I’m not sure are accurate or fair.

For example, waterproofness. For a while, people have said that stitchdown is less waterproof than Goodyear welts, but I’ve also heard that they are more waterproof.

“Realistically, if your upper is not made of waterproof leather, it doesn’t matter; water will get in,” says Dave. “Also, there are essentially holes in the upper of a Goodyear welted shoe as well. Water can get in between the welt and the upper. First, it will go into the cavity under the shoe, but after that, or if you are walking through a 2-inch puddle, it can totally get in. It will just rise up through the rest of the shoe.”

The water resistance — not waterproofness — of stitchdown and Goodyear welt is comparable. It’s going to depend a lot on how the entire boot is made and the materials you use. For example, a desert boot, which is obviously not designed for wet environments, is not going to have the same water resistance as a pair of sturdy hiking boots that are stitchdown.

“If you use a chrome-tanned lining, which is very water-resistant, that’s going to add to your water resistance, says Dave. “If you’re properly gluing and abrading the upper when you attach the sole or the midsole, that’s going to make a huge difference in whether water gets into the shoe or not.”

Between Goodyear welt and stitchdown, however, the water resistance is comparable and depends on how the rest of the boot is made.

Conclusion

In practical terms, for people wearing boots casually, or maybe for a bit of hiking and manual labor here and there, the main difference is in the company selling the boot rather than the construction method itself.

For people who are wearing boots casually, and maybe for a bit of hiking and manual labor here and there, the main difference is in the company selling the boot, rather than the construction method itself.

Jake from Almost Vintage Style

On average, boots made with stitch-down construction are chunkier and larger and have thicker midsoles. This is because the companies that use this construction method generally make that type of boot more often.

For most of us, it doesn’t make too much of a difference. Some people will swear allegiance to one or the other, but I have boots made with all types of construction methods and enjoy all of them for what they are.

“Sometimes I like the wider midsole and double row stitchdown look from a pair of stitchdown boots, but sometimes I think a Goodyear welt looks better.” Personally, Jake suggests “that you try at least one pair of each construction method.”