Goodyear Welt vs Stitchdown Construction Pros & Cons

Goodyear Welt vs Stitchdown construction is hotly debated in the heritage boot community. These are the two most commonly used construction methods for high-end shoes and boots and there’s little agreement about which one is the best.

And a lot of people are unsure exactly what these two terms mean. Even those who know the general differences between the construction methods.

So, we asked boot expert Jake from Almost Vintage Style to break down the two construction methods.

Key Takeaways: Goodyear Welt vs Stitchdown Construction

- Both are durable and repairable, but it’s easier to find a cobbler to repair and resole Goodyear welted.

- You might have to send stitchdown boots to the original manufacture.

- Both are comfortable, but construction is only one aspect of comfort

- Stitchdown are more water resistant.

- Stichtdown is generally more expensive than Goodyear welted boots.

- There are exceptions to all of these rules.

What Is a Goodyear Welt?

- A Goodyear welt is the actual welt or piece of leather that connects the insole to the outsole

- Durable and resoleable throughout its life

- It has a good balance between durability and flexibility

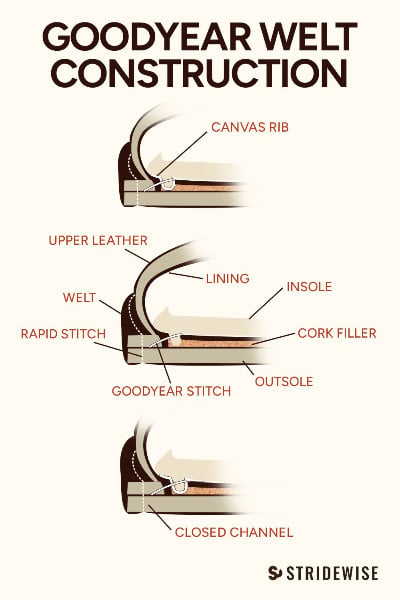

We’ll start with the Goodyear welt, as that’s likely the most common form of boot construction. Here’s a basic step-by-step of making one:

- First, attach a canvas rib to the insole of a pair of boots or shoes with glue,

- Sew that to a piece of leather, which is the actual welt.

- The bootmaker sews the welt to the midsole and outsole of the boot/shoe.

Different Kinds of Goodyear Welts

Unsurprisingly, the Goodyear welt has several different types that can increase the boot’s durability or water resistance.

Channeled

“Firstly, some Goodyear welted footwear brands use a “channel” instead of a canvas rib to attach the welt to the insole,” explains Jake, “The bootmaker carves a channel into the insole with a machine and then stitches the welt to the flap of leather attached to the insole.”

Some bootmakers claim it’s a more durable construction method than using the canvas rib called gemming.

Further Reading

Carmina Chelsea Review

See an example of a channeled sole in our Carmina Chelsea boot review Read More →

Storm Welt

“The other main modification of the Goodyear welt is the storm welt.” says Jake, “The only difference between this and a normal Goodyear welted boot is that extra leather sticks up above the welt and sits next to the upper of the boot.”

The construction method is otherwise the same as Goodyear welt, but that “lip” on the storm welt helps keep rain from getting into the boot.

Goodyear welted shoes and boots are pretty much the standard of good quality, resoleable boots and shoes. It is basically a more mechanized, streamlined, and cheaper way to make hand-welded footwear.

“It produces boots that can last a lifetime,” Jake points out, “only if the bootmaker uses high-quality materials, properly constructs the boots, and the owner properly cares for the boots.”

[Related: Hand welted vs Goodyear welted – Which Is Better?]

What Is Stitchdown Construction?

- The bootmaker stitches the upper to the midsole/outsole without a welt

- The upper leather attaches to the midsole

- Common no serious work boots such as those used by wildfire fighters

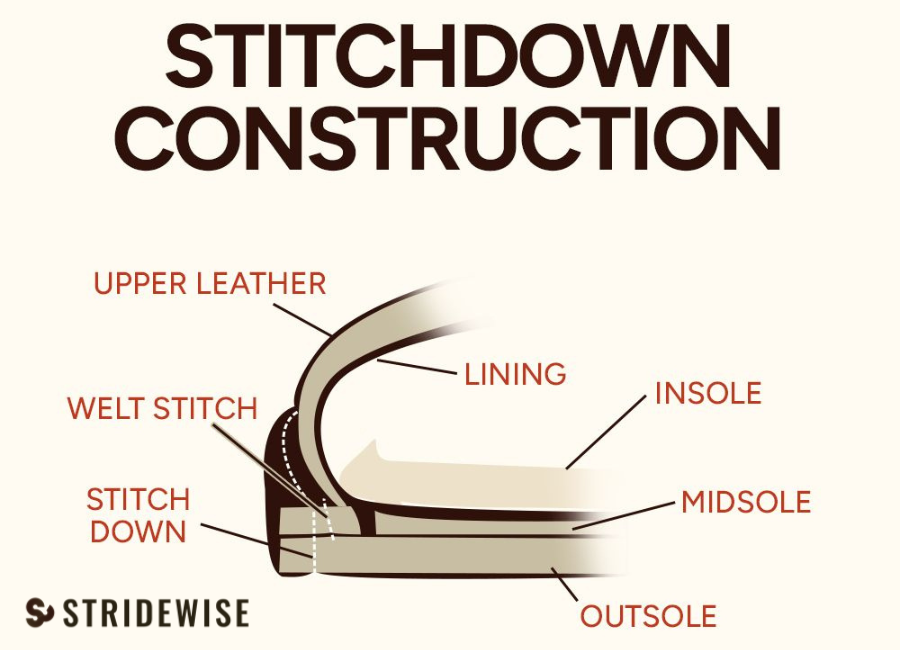

“Stitchdown construction is simpler to understand.” Jake says, “The bootmaker pulls the upper’s leather out over the midsole and then attaches it to the midsole and outsole with a rapid stitch.”

With stitchdown, it’s almost as though the upper takes the place of the welt itself. Bootmakers attach the upper to the midsole and outsole in one of two ways:

- With one single stitch that goes through the midsole and outsole, like a Goodyear welts.

- More commonly, however, the bootmaker attaches the upper to the midsole and outsole with two stitches, called “rapid stitches.”

- The first rapid stitch on the inside attaches the upper to the midsole.

- Then the second stitch goes through the upper, midsole, and outsole. (The uppers are sometimes glued to the midsole.)

“Stitchdown construction has a recognizable double stitching,” he says, “but some only use one row of rapid stitching. Also, other construction methods use two rows of stitching that aren’t stitchdown. Two rows of thick white stitches often indicate a pair of stitchdown boots.”

Serious work boots have stitchdown construction. “Many of these brands are from Pacific Northwest.” Jake also says, “There bootmakers specialize in making boots for loggers and firefighters. Stitchdown construction is also fairly water resistant.”

“But,” he adimits ” it’s not exactly clear why bootmakers use stitchdown for these types of workboots, the claim is that stitchdown boots are more durable.”

Stitchdown vs Goodyear Welt: Durability

- Durability depends more on more factors than simply stitchdown vs. Goodyear Welt

- If you do not need serious work boots for your job, either should effectively be as durable for you

- Stitchdown or hand welted work boots (like White’s) are more durable, so if you need ultimate durability, go that route

“Companies often say that stitchdown construction makes for more durable boots, but this is not always the case.” Jake says, “Desert boots like the famous Clark’s desert boot have stitchdown construction. But these boots and their crepe rubber soles are far from the most durable boots.”

[Learn More: Pros and Cons of crepe soles?]

Are Stitchdow or Goodyear Welt Boots More Comfortable?

In most cases, the owner will hardly notice the difference between two pairs of nearly identical boots that use these two different construction methods.

“I have owned two pairs of Viberg boots.” says Jake, “One had their famous double-row stitchdown construction, and my second pair had a 360-degree Goodyear storm welt.

Both boots use horsehide (albeit from different tanneries) and use the 2030 last. I noticed far more of a difference in terms of feel and comfort based on the upper leather and the soles than the construction. “

This is not to say that there are no comfort differences between the construction methods, but for many guys, the construction is more of an aesthetic difference than anything else.

Use cases for Stitchdown Boots

Wesco makes their Highliner for people who climb poles and/or trees for their job. Wesco and Nick’s make stitchdown boots for fighting wildfires. Nick’s even has a boot specifically for asphalt workers. These boots have to stand up to more punishment than most footwear does, and they’re all made with stitchdown or hand welted construction.

Does the stitchdown method make a boot more “heavy duty” than a Goodyear welt? “That is hard to say.” Jake expalins, “Nick’s basically says as much on their website, but I take anything a brand tells me with a grain of salt.”

Are Stitchdown Boots More Durable than Goodyear Welted Boots?

“A good counterpoint is White’s.” Jake explains, “They don’t actually make their most hardcore boots with stitchdown but with handwelted construction — a more labor-intensive form of Goodyear welts. That would help prove that stitchdown is not inherently “best” for work boots.

Plus, as I mentioned before, some makers use channelled leather insoles to attach their welts rather than using canvas to attach the welt, which might make a Goodyear welt more “durable” than stitchdown.”

That’s just one example of the range of factors that affect the boot’s durability. Others include the upper leathers, the insole leather, the midsole leather, the outsole material, the shanks, the heel counters, the stitch material, how soundly the boots are put together, etc.

This is just a long way of me saying that you should not buy a pair of stitchdown boots because you are worried that Goodyear welted boots are not durable enough for you.

Jake from Almost Vintage Style”

You don’t need to buy stitchdown boots because you are worried that Goodyear welted boots are not durable enough for you.

If you are reading this because you are interested in boots as a hobby, then your Goodyear welted boots are more than tough enough.

Further Reading

The Best Boots for Men

Looking for a durable, resoleable boot? We’ve put together the ultimate list to save you money and time. Check out how →

Goodyear Welt vs Stitchdown: Resole-ability

- Goodyear welted boots and shoes are quite simple to resole for most cobblers and shoe repair shops.

- Stitchdown construction is much more difficult to resole

One of the first things that comes to mind when comparing the two is can it be resoled?

“Most people who own stitchdown boots get resoled by the company that made them. This gives you fewer options for repair.” Jake explains, “But if you don’t mind sending your Wescos back to Wesco, then it’s not a problem to get them repaired.”

“Even among cobblers,” he says, “you’ll get a lot of conflicting answers about resoling stitchdown boots. The long and short of it is that some will do it, and some won’t. Call your cobbler in advance.”

A cobbler can convert Stitchdown boots to Goodyear welt if desired. Role Club has done this in many cases, and some other shops may offer this as well. If you are interested in this, however, make sure you contact the repair shop beforehand to make sure.

Overall, Goodyear welted boots are more straightforward to have resoled.

Goodyear Welt vs Stitchdown: Comfort

- Goodyear welt boots will generally be more comfortable out of the box

- Stitchdown boots will often offer greater support for your feet over long periods of time

As with durability, comfort has a lot more to do with the other factors beyond the construction. Comfort is extremely subjective.

“For example, my softest, most flexible, and most sneaker-like boots are my Clark’s desert boots.” Jake points out, “They are made with stitchdown construction. At the same time, my most rigid and heavy boots that give the most support are my Wesco and Nicks boots. They are also made with stitchdown construction.”

“I have had two pairs of Vibergs, with one being double row stitchdown and the other being Goodyear welted.” he says, “They both feel quite similar overall. The Goodyear welt pair does feel more flexible. “I have had two pairs of Vibergs, with one being double row stitchdown and the other being Goodyear welted. They both feel quite similar overall. The Goodyear welt pair does feel more flexible.”

The flexibility is partly due to the full leather sole instead of a Dainite rubber outsole. “My Nicks Robert boots have great arch support,” he says, “but that is because of the design, not the stitchdown construction.”

In general, Goodyear welt boots will be lighter and more flexible. If this is what you prefer, start with that. If you want to try boots with more foot support, arch support, but more weight, then stitchdown boots are good options.

Goodyear Welt vs Stitchdown: Pricing

- Stitchdown construction tends to be the pricier of the two

Goodyear welt are easier to make and the less expensive option of the two. Truman Boot Co. says on their website that their Goodyear welted boots are less costly to make than a pair of Stitchdown boots.

Aside from desert boots, it is rare to find any boots made with stitchdown for under $400. Most of them are in the $500 to $800 range. Again, there are other factors that go into a boot’s price, but Goodyear welted footwear is often less expensive.

Goodyear Welt vs Stitchdown: Water Resistance

- Stitchdown construction is more water resistant than Goodyear welts

It might be surprising to learn that stitchdown construction is more waterproof than normal Goodyear welt construction.

On stitchdown boots the upper is sewn and glued to the midsole, preventing water from entering if constructed properly. Basically there’s more gaps in a Goodyear welted boot for water to enter.

Unsurprisingly, there are some exceptions to this. Stitchdown boots are often only stitched 270 degrees around the boot rather than all 360 degrees, meaning water could get in through the heel area.

Then again, Goodyear welted boots can also use storm welts, which incrase the water resistence. Is a 360 degree storm welt boot more waterproof than a 270 degree stitchdown boot? “I honestly do not know.” Jake admits, “What I am fairly certain of is that a 270 degree stitchdown boot will likely be more waterproof than a 270 degree Goodyear welt boot. ”

Conclusion

In practical terms, for people wearing boots casually, or maybe for a bit of hiking and manual labor here and there, the main difference is in the company selling the boot rather than the construction method itself.

For people who are wearing boots casually, and maybe for a bit of hiking and manual labor here and there, the main difference is in the company selling the boot, rather than the construction method itself.

Jake from Almost Vintage Style

On average, boots made with stitch-down construction are chunkier and larger and have thicker midsoles. This is because the companies that use this construction method generally make that type of boot more often.

For most of us, it doesn’t make too much of a difference. Some people will swear allegiance to one or the other, but I have boots made with all types of construction methods and enjoy all of them for what they are.

“Sometimes I like the wider midsole and double row stitchdown look from a pair of stitchdown boots, but sometimes I think a Goodyear welt looks better.” Personally, Jake suggests “that you try at least one pair of each construction method.”

At least in my opinion, the biggest difference comes down to repairability. With a stitchdown, any damage to the “welt” during a resole is damage to the upper, and it is much easier to replace the welt in a Goodyear construction than the upper of the entire shoe. That said, this is usually offset by most of the larger stitchdown makers like Nick’s offering factory rebuild services where they replace the entire upper on the original lasts and such.

I agree. I think it’s worth being practical though, stitchdown can maybe only be resoled 2 or 3 times while GYWs are infinite, but you’re unlikely to need more than a few resoles. Of course it depends on how you’re wearing them!

I have had single stitch GYW boots that have lasted through 10 years of rough duty daily wear. Albeit, these were made of elephant hide and were high quality boots and I know how to care for my boots (and do). Simple cowhide boots have given me the same durability even in corrosive solvent, again well cared for.

What I won’t do is adapt the current style of double outsole stitching on cowboy boots that appear to be fashioned for circus wear by low grade clowns.

Can anyone recommend a DRESS shoe for men’s that’ s made around the Stitchdown Construction Method?