Hand Welted vs Goodyear Welted Boots | Yes, One Is Tougher

Expert Verified By: Sandeep Parihar | Co-Owner: BLKBRD Shoemaker

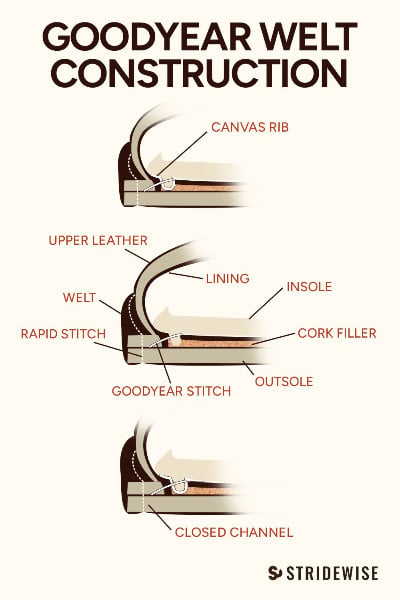

You’ll often see the words “Goodyear welt” next to the words “gold standard,” and it’s certainly become the standard way to make footwear that can be resoled. If a cobbler can only resole one kind of boot (and that’s often the case), it’ll be the Goodyear welted kind.

Making a complex and multi-layered shoe, the Goodyear welt machine was invented in the 1860s to replace hand welting, invented in the early 1500s.

Hand welting, of course, was much more manual and time consuming than the machine that replaced it — but the two processes don’t produce exactly the same shoe.

Key Takeaways: Goodyear welt vs Hand welt

Goodyear welting is the most common way to make footwear that can be easily resoled. It’s a machine that replaced hand welting in the 1860s.

Technically, hand welted boots are more durable, mostly because Goodyear welts have more glued components that can come unstuck with wear.

Practically, the average person is unlikely to notice any difference.

The main reasons some enthusiasts prefer hand welted boots are that they enjoy the feeling of the thicker leather they use, or because they respect the skill and labor.

A Goodyear welt machine lets a footwear brand produce far more products to sell, but there remain some purists who prefer the rarer and more expensive hand welt. Is the difference between the two worth hundreds, sometimes thousands of dollars more?

There are technical and subjective reasons for making the choice. To best articulate them, I drew from interviews I’ve had with David Corey of Old Speed Manufacturing, Bagus Satriow of Sagara Bootmaker, Rizky Afnan from Onderhound, Affan Mohammed, a third-generation shoemaker at Bridlen Shoes, and Pradeep Parihar from BLKBRD Shoemaker.

Goodyear Welt vs Hand Welt: The Most Important Difference is Glue

- Most inexpensive shoes are cemented: the upper is simply stuck to the sole with glue.

- Goodyear welted shoes are easier to resole because instead of being attached to each other, the upper and the sole are attached to a strip of material (the welt) between them.

- On a Goodyear welted shoe, the welt is sewn to a strip of canvas that’s glued under the insole

- On a hand welted shoe, the welt is sewn to the insole itself

- Because there’s no glue that can come unstuck with wear, hand welted shoes are technically more durable

I’ve visited boot factories and workshops all over the world: some Goodyear welted, some hand welted. In the absolute simplest, most reductive terms, those bullet points I just wrote out above this paragraph describe the main differences.

“In short, a Goodyear welt construction is where the upper is stitched to a leather strip called a welt, which is attached to a piece of canvas under the insole,” explains Oldspeed Mfg’s Dave. “That welt provides a secure anchor for the outsole — so when the sole wears out, you can peel it off and glue on a new one without disturbing the upper.”

We’ve been saying Goodyear welted shoes have the upper and the sole attached to a welt between them. But technically, the welt is sewn through a strip of canvas that’s glued under the insole.

A lot goes into this complex kind of footwear, but here’s the rub:

- if it’s Goodyear welted, the welt is sewn through canvas that’s glued under the insole.

- if it’s hand welted, the welt is sewn into the insole itself.

So on a hand welted shoe, the welt is sewn right into the insole itself by cutting a channel into the leather insole.

“In true hand welting, the shoemaker cuts a channel into the leather insole so that stitches lie flush and protect the stitch row over time,” says Blkbrd’s Sandeep Parihar. “This detail helps illustrate why hand welting is so labor intensive.”

Because hand welted shoes don’t have that glued component under the insole that can come unstuck, you can argue that Goodyear welted shoes have a failure point that hand welted shoes don’t.

Because there’s no glue under the insole that can come unstuck, you can say that Goodyear welted shoes have a failure point that hand welted shoes don’t.

“I hand stitch through a flap of leather cut out of the insole itself,” says Rizky Afnan of Indonesia’s Onderhoud Handmade. “There are fewer failure points in a hand-welted boot, which can justify the higher price for some.”

Channeled Insole Goodyear Welts: A Rare Midway Point

It’s almost not worth mentioning because it’s so rare, but when I visited Bridlen in south India, they introduced me to a third approach: channeled insole Goodyear welt.

Here, the welt is sewn into a channel that’s been cut into the insole, just like with a hand welted shoe. But instead of sewing the welt on by hand, you use a Goodyear welt machine.

In other words: it combines the durability of a hand welt with the speed of a Goodyear welt.

“The flexibility and the break in period is significantly reduced as well compared to a Goodyear welt,” says Bridlen’s head shoemaker Affan Mohammed. “Because the materials are stacked in parallel, rather than sewing through a rib that’s perpendicular to the rest of the material.”

Not many people do it, but Bridlen does! Viberg has also tried it with a few models, and I’ve heard this technique is more common on cowboy boots as well.

Made with leather from the world's best tanneries and innovative techniques that combine 19th and 21st century shoemaking, Bridlen is a very rare jewel whether you're after dress shoes or hardy boots.

Other Reasons to Prefer Hand Welted Shoes

The presence or absence of that glued on canvas rib is the most important difference, but there are a few others.

Thicker Insole, Less Cork: Hand Welts are Probably More Comfortable

The insole is usually what’s under your feet (some differentiate between insole and lasting board and footbed, but we’re not getting into all that).

While Goodyear welted brands have some flexibility as far as how thick they want the insole to be, it has to be unusually thick to hand welt. Because you need enough leather to be able to carve out that channel in the insole.

A lot of guys prefer a nice, thick leather insole because the leather conforms to your foot’s shape with wear. The more leather, the more material your foot can sink into, the more “custom” the boot will eventually feel after a lot of wear, and the more support the wearer feels.

When you make a strip of leather (the welt) run around the perimeter of the insole, you’re leaving a gap in the middle of the insole where there is no welt. That “cavity” gets filled with cork, which does have benefits: it also conforms to the foot’s shape, it manages moisture, and provides some rudimentary shock absorption.

But as you can see from the photo above, taken after I removed the insole of my well worn Red Wings, the cork compresses and redistributes over time.

Hand welted boots use a lot less cork (often none at all) because their thicker insoles and tighter construction shrinks the size of the cavity.

And when choosing between more cork or more leather, most enthusiasts pick leather without thinking twice. A thicker insole means a better fit — with time.

More Durable Stitching

Before even mentioning the canvas, this is the first thing Bagus Satriow of Sagara Bootmaker told me when I visited him in Indonesia and asked about the benefits of hand welting.

“Goodyear welt machines use a technique called lock stitch, with two threads looping in and out of the welt. If the stitch breaks, you just need to pull on it, and all the stitching will rip out,” he says. “But when we hand welt, we only use one thread. The result is if the thread is cut, it will not break through to other areas.”

Some folks argue that lock stitches are still better because although it’s worse when they break, they’re less likely to break in the first place than the other method. Others dispute this!

Metaphysics: Hand Welted Boots are Harder to Make

- Hand welted boots contain more of the shoemaker’s time, skill, and heritage

- Some enjoy this stronger bond with the shoemaker and his teachers of generations past

- Hand welted boots are inarguably more valuable

The other major benefit of hand-sewn welted boots over Goodyear welted boots is the least tangible one, but it’s probably the most common reason people buy hand welted footwear — even if they won’t admit it.

It’s the vibes, man.

I’m being playful here, I mean no disrespect to the shoemakers! I mean that many people buy hand welted boots because they like knowing that they’re wearing a product that’s hard to make. There’s more art in them!

Hand welted boots embody more time, labor, and history. Unlike some expensive products, these ones are literally more valuable than the alternative: they require more time and training to make.

“We’ll always offer hand-welted boots because it’s important to support our highly skilled craftspeople and give back to the community,” says Blkbrd’s Pradeep. “Think of the difference between a handmade sculpture and one made by a machine. The handmade piece has a human touch. People love wearing something harder to make — something shaped by skill, time, and care.”

Wrapping Up

This article in no way is bashing Goodyear welt construction.

Practically all my footwear is Goodyear welted. It takes skill, it’s vastly more durable and waterproof than sneakers, it’s the easiest to resole, and here’s the most important part: very few people will need or notice the benefits of hand welts. Goodyear welts are more than tough enough for 99 percent of people.

Wearing any kind of resoleable shoe is sustainable too, but the biggest reason I buy them is to help preserve the art of making them. This is the case for any kind of resoleable shoe, including Goodyear welts!

And it’s especially the case for hand welting. Buying hand welted helps preserve an artform and provide a livelihood for a rare type of tradesman who deserves all the customers he can get.

Plus, some brands aren’t even charging that much:

Great Hand Welted Boot Brands, In Order of Price

Blkbrd Shoemaker in India have some models, like their bestselling Dixon boot, going for under $250. It’s hard to find a Goodyear welted boot for that price, let alone hand welted and hand lasted.

Bridlen Shoes, also in India, do the channeled insole Goodyear welt I mentioned earlier. It uses more machinery than a real hand welted shoe, but it has nearly all the same benefits. (I think they use a lock stitch, but it’s fine.)

Indonesian brands: If you ask for their cheapest makeup — domestic leather, single midsole — most brands will give you a hand welted, hand lasted boot for under $400. Note that they’ll take several months to arrive, unlike the Indian operations.

Iron Boots: Helmed by a famous visionary in southern China, this brand only uses the finest leathers and many models are under $1000. My boots were handsewn stitchdown, which is harder to resole, but I’m sure he’d make you a handwelt? If not, get handsewn stitchdown, it’s cool too.

Japanese brands: The most premium boot industry on Earth, many brands here have eye popping skill and quality control. Just be ready to pay four figures.

Further Reading

10 Most Comfortable (kinds of) Boots

I discuss six kinds of comfort and list brands that make better-fitting boots than you might have thought possible. Learn more →