Thursday vs Nicks Boots: The Challenger Review

Sometimes, I get to visit brands when they have new releases. I went to Minnesota to see Red Wing’s Iron Ranger Traction Tred, I visited Filson for their 125th anniversary collection, and since I live in Manhattan, it was easy to visit Thursday Boot Company and grill them about their new line of super duper premium boots they’re calling the Black Label Collection.

There are a few Black Label boots out now, but I grabbed the first product in the line, The Challenger, so I could spend a few weeks stomping around New York and give you my thoughts — and compare it to what I’m pretty sure this boot is meant to be “challenging”: the Urban Logger from Nicks Handmade Boots.

I’ve reviewed over a hundred boots since starting this site and YouTube channel over a hundred years ago, and along the way I stopped by Nicks and reviewed the Urban Logger myself, so I’m in a pretty good position to tell you how the new Thursdays compare to their cheaper boots and how they compare to what might be America’s greatest Pacific Northwest brand.

This hybrid boot puts the best features of serious outdoorsman footwear on an ever so slightly more low key design so that it can be worn in the city or the woods.

Rare leathers from world-class tanneries, a chunky sole, stacked leather Woodsman heel, and laborious stitchdown construction for under $400.

What Is a Pacific Northwest Boot?

- Built for or inspired by outdoorsmen of the Pacific Northwest

- Brands typically have dedicated boots for loggers, firemen, and linemen

- Stitchdown construction is common

- Logger boots are PNW boots with a particularly tall heel, arch, and shaft

Whether you’re invoking Nicks or not, it is undeniable that the Challenger boot is positioned as a Pacific Northwest boot.

Boots, of course, have many different categories. You’d put both Thursday and Nicks in the “heritage boot” category because they’re traditionally made, resoleable leather boots. But then there a subcategories like riding boots, midwestern heritage work boots, service boots, it goes on and on.

But the Pacific Northwest (“PNW”) category refers to brands like Nicks, White’s, Wesco, JK, and Frank’s. They all make boots that are heritage, but PNW boots stand out for ostensibly being worn (or inspired by) the tough outdoorsmen of the PNW who engage in the region’s traditional industries of logging, firefighting, lineworking, and hunting.

PNW boots are made even tougher than work boots like Red Wing Heritage or military-inspired service boots. They tend to be made with uncommonly thick leather uppers, more leather underfoot, tall shafts, and stitchdown construction instead of the more common Goodyear welt. They also tend to cost well over $500.

That said, the Urban Logger and the Challenger are more like fusions of logger boots and city boots. Like, logger boots are often 10 inches tall and have spikes on their soles. These are meant to be more city-friendly versions of the boots that can still withstand an insane amount of wear and tear.

Why Thursday Boots Are So Popular

Now, if you’re a fan of Thursday Boot Company, the PNW boot is probably very alien to you.

Thursday has always focused more on what you might call city boots. (Because even people in the city need the benefits of stable and durable and water resistant footwear!)

In addition to unselfconsciously targeting a more youthful and style-oriented customer base than PNW brands, Thursday also stands out in the heritage boot crowd by using synthetic insoles to help with shock absorption and break in, and by somehow keeping their resoleable boots under $200.

Now if you’re a PNW boot guy those elements — easy break in, synthetic insole, low price, modern design — are alien to you. But Thursday wants your business.

Introducing Thursday’s Black Label Collection

- Higher end construction and materials than Thursday’s classic boots

- Leathers from world renowned tanneries

- All leather internal components

Since I sat down with Thursday’s co-founder, I’ll let him explain.

“We decided to create the Black Label Collection, and some of these new styles we’re coming out with, (because) there’s been a lot of people who just love the concept of Thursday and what the brand’s all about (…) but want something beefier,” says Nolan.

There are guys who like boots and there are boot guys for whom nothing short of the best will suffice. Some hobbyists turn their noses up at Thursday’s Captain for being made with synthetic insoles, thinner leather to emphasize comfort, uppers from Mexico instead of Japan, and for having a design aesthetic more geared toward modern tastes.

In my words, this collection is intended to stretch Thursday’s capabilities and see how high quality they can get — and to show the purists that this brand is capable of satisfying even the most exacting of tastes.

So I would say that what defines the Black Label Collection is, we’re using just super high end leathers from the most renowned tanneries in the world. Really, all the components are just the highest end version of every component, and they’re made in super small batches. I’m talking five-unit batches by our most senior artisans, and limited edition by nature.

Our plan is to do some of that special upper echelon stuff for the true boot geeks such as ourselves — and have a lot of fun with it.

This collection has featured whole-cut Chelseas, stitchdown moc toes, and Goodyear welted sneakers made of leather from five very famous tanneries, but let’s get back to the Challenger.

Thursday’s Challenger Boot: The Specs

Here’s a nice listicle version of the boots’ standout elements.

All Leather Internal Components

While Thursday usually emphasizes better shock absorption and comfort with synthetic insoles, a lot of boot guys prefer all leather underfoot because it does a better job of molding to the shape of your foot over time.

The regular Thursdays still have cork filling and a leather midsole, so they do still mold to your foot’s shape — but not in quite the same way as all leather.

Another thing: usually, a boot has components to stiffen or reinforce the toe and heel. Most brands (even the high end ones like Nicks) use a plastic impregnated fabric called celastic, or thermoplastic. But many boot nerds often prefer leather — maybe because of how it molds to your foot, maybe it breathes better, or maybe just because it’s more “natural.”

You’ve got that on the Challenger too: leather toes and heels with no plastic to be found.

“All leather internal components” means one more thing: a leather shank. A shank is a hard strip of material (usually steel) that’s inserted under the midfoot to provide more stability to the boot.

High end brands (like Nicks and White’s) often use stiff, vegetable tanned leather shanks instead of steel because it does the same job while having a bit more give to it.

Name Brand Soles

The most revered soles for boots come from Dainite, Vibram, and Dr. Sole. They’re expensive, and many brands (even darlings of the boot community like Grant Stone) will make their own soles that are inspired by those designs, but Thursday put a real Vibram outsole on the Challenger — like Nicks!

Thicker Leather

Usually, Thursday’s leather uppers are 1.6 to 1.8 millimeters thick. Tough break ins are the biggest source of complaints and returns for a boot brand, so they really focused on limiting that by using leather that’s thicker than a dress shoe but thinner than work boot. But the Challenger has an upper of 2 to 2.2 millimeters.

Stitchdown Construction

Thursday’s Challenger, Nicks Urban Logger, and any PNW brand worth their salt emphasizes stitchdown construction.

Without getting too technical (you can read this zillion-word breakdown of stitchdown vs Goodyear welts if you want that), most good resoleable boots are made with the Goodyear welt, but you can also make one with stitchdown construction. Goodyear welting is done by a machine, which was invented to replace the more laborious operation of hand welting. Stitchdown can be done by hand (see Iron Boots) or by machine, which is the case with Nicks and Thursday.

Stitchdown is harder to make and harder to resole than the commonplace Goodyear welt, especially when it’s double row stitchdown like these boots have. But this is the kind of build you’d expect on an authentic Pacific Northwest boot.

There’s a case to be made that stitchdown is more waterproof and durable than a Goodyear welt. Normally, I tell guys they’re splitting hairs when they let that guide their purchase — but when you’re getting a PNW boot that’s theoretically meant to hold up in the region’s punishing and frosty wilds, I understand the preference for stitchdown.

If everything else on this PNW boot were was the same but Thursday made it with a Goodyear welt, it would be weird.

High End Leathers

Most of Thursday’s leather comes from Lefarc tannery in León, Mexico, where the boots are made. Lefarc is great and famously sustainable: they do leather for huge brands like Ariat, Tecovas, Schott NYC, Saddleback, Huckberry, Timberland, and more. They actually invited me there once for a leathermaking workshop!

But brands like Nicks use leather from super premium tanneries that would not let you make a boot for under $200 like Thursday.

Now, indisputably, the list of best tanneries on earth includes Chicago’s Horween leather company for boot leather, England’s CF Stead for suede, Italy’s Maryam for horse, Japan’s Shinki Hikaku for cordovan, and Pennsylvania’s Wickett and Craig for vegetable tanned leather. (All these facilities make many kinds of leather; for instance, Horween rivals Shinki for cordovan. But I’m giving you the Cliffnotes here.)

I think it was when Thursday announced the tanneries supplying the leathers for the Black Label Collection that the boot “community” really sat up and took notice. So far, the Challenger has been released in Shinki cordovan, CF Stead suede, Horween’s “Whiskey Predator,” two kinds of Maryam horsebutt — all of the biggest names in the business.

My Challenger’s Rambler Leather

My particular boots are in Stone Rambler, a color that’s right between grey and brown so you can wear it with cooler or warmer colors. If you recognize that name, there’s a good chance it’s because of Truman Boot Company, an Oregon outfit that has made offering several shades of Rambler part of the brand’s identity. Our pal Dale Basista even wrote us this cool article about Rambler leather.

For those who are less in the know, Rambler is a thick suede that’s waxed for extra water resistance. If you look closely, you can see veins in the boot’s upper: Rambler really looks like it’s been carved out of an animal’s side.

It’s a misconception that suede has to be thin: it’s suede if the top layer has been split off from the rest of the hide and the fleshy fibers beneath are exposed. But that doesn’t mean it’s thin or delicate: you can keep enough of the rest of the hide that you can have “suede” that’s thicker than most “full grain” leathers. Rambler is one such example.

It’s also beloved by boot guys because of the way it patinas: the wax slowly wears away and the suede’s nap becomes more pronounced. You can always rewax it if you want, but hobbyists tend to take great pride in wearing all the wax off with wear and in the unique aesthetic it produces.

Where Nicks Boots Beats Thursday

With Thursday offering so much boot for so much less money (more on the price later), does Nicks have an edge? Sure, plenty.

More Widths

The Urban Logger’s sizes run from 4 to 13 and the Challenger from sizes 6 to 16. Thursday wins for bigger dudes but Nicks will make your boots two different sizes if you like, and they offer more widths than any other boot company I’ve ever seen.

There are eight widths to choose from, including two narrow fits (B and C) and up to FF for wide guys. While Thursday has plenty of wide width boots, none are made for the Challenger just now, and when they are wide they tap out at EEE. To be fair, it’s very rare for any brand to offer wide sizes, let alone extra wide like that, but Nicks has them beat.

It’s also worth emphasizing the narrow sizes. I was recently told I’m probably a 12C and not an 11.5D, but no one makes C width boots… except Nicks. (And Allen Edmonds and one or two others, but it’s mad rare.)

They’re American Made

There’s plenty of crossover between guys who like Americana style boots (which these are) and guys who value American-made boots. Nicks are made in Spokane, Washington, while Thursday’s are made in Mexico. Well, their Vanguard and Logger boots are made in the USA, but the Challengers aren’t, and I totally respect if that’s your dealbreaker.

More Leather Options

The Challenger gives you five or six uppers to choose from; Nicks has over thirty. Most, if not all, are from American tanneries that don’t have quite the cool-kid-cachet of the Black Label Collection. Still, Nicks will sometimes have the odd funky leather for the more daring dude; the oxblood-colored shrunken bison leather that’s currently on the site sounds pretty cool.

More Customization

I could say that the standard Urban Logger is made with a celastic toe and no toecap, two areas where the Challenger differs, but you can actually customize your Nicks boots to have a toecap and an unstructured (no celastic) toe if you want. I prefer the eyelets on the Challenger (they hold the laces better), but I could have chosen from three other kinds of eyelets on the Nicks.

Nicks is really, really impressive with the control they give you over your boot. You can get:

- a toecap if you want

- a choice of three soles

- four kinds of eyelets

- speed hooks or no speed hooks

- a pull loop

- a choice of edge color

- an unstructured toe or a celastic toe

- a choice of how your shaft is finished (eg. rolled edges, raw, padded collar)

- a taller boot of 8 inches

- even a moc toe boot instead of plain toe (or cap toe)

Making most of these choices costs extra, of course, and it’s not uncommon for the boot to wind up over $700, but that’s still a big advantage for Nicks. It really gives you an extra sense of ownership over the boot.

Where Thursday Beats Nicks

These boots have a ton in common: the hybrid city-boot-logger-boot design, tall heel, double row stitchdown, Vibram sole.

But there are some differences that will help you decide between the two.

The Break In

PNW boots are famous for tough break ins, and Thursday gave themselves the challenge of keeping the internal components all leather — no cheating with softer synthetics.

So they did two interesting things to reduce break in:

- as you can see in the picture above, they cut grooves into the midsole to make it more flexible.

- They also lined the insole and heel with vachetta leather, a kind of unusually soft, vegetable tanned leather that’s better known for being used on luxury briefcases.

I was expecting a hard break in with the Challenger but this design works: I was able to walk comfortably in them from day one.

The Arch

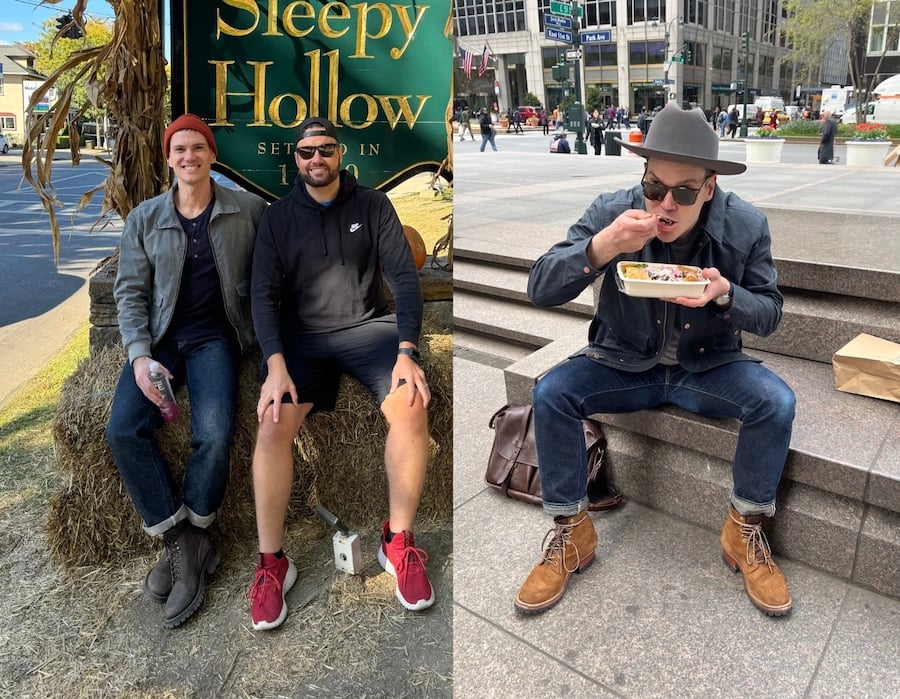

Big heels are common in certain work boots for helping you secure on ladder rungs, dig shovels into the ground, and other uses. The Challenger and the Urban Logger both both have huge heels, but the arch is just a little higher on Nicks: I clocked it at about a quarter inch higher than Thursday’s.

When walking around in both boots at once (above) and then in both pairs separately, I believe that higher arch is responsible for what I think is a critical difference: the Urban Logger’s design pitches me forward a little when i’m walking. While they both have logger heels, I feel more like I’m teetering when I’m in the Nicks.

The Craftsmanship

This is a loaded term and it usually refers to elements that the average “rugged” guy wouldn’t care much about.

Still, plenty of customers in this higher-end space value elements that suggest great care and experience on the part of the bootmaker like stitch alignment, heel smoothness, and stitches per inch (SPI).

If that’s you, you’ll be impressed by the fact that, on average, the Challengers’ stitchdown has a higher SPI: they’re pretty consistently five per inch while Nicks often drops to four. By boot nerd math, that makes the Challengers more skillfully made, at least in the SPI.

If you are new to the world of high end boots, you probably think judging something like SPI is ridiculous, particularly since it doesn’t make a difference for durability. But the Black Label Collection is targeting the kinds of guys who look for this kind of stuff and even though they’re both machine sewn, the Challenger’s SPI is higher.

International Leathers

While the Challenger comes in only a few leathers at a time (max five so far, and they run out fast), they deliberately selected them from luxury tanneries from across the world in a solid range of aesthetics and colors. Nicks just focuses more on toughness and American origin than, say, artfulness in tanning.

The Price

Most of the Challengers cost $349. Cordovans are $549, one of the horsebutts is $369, but even though they’re made in Mexico and Nicks are made in Washington, this is still a bonkers price.

Rare leathers from world-class tanneries, a chunky sole, stacked leather Woodsman heel, and laborious stitchdown construction for under $400.

The Urban Logger starts at $629, but once you’ve customized them a little, it’s common for them to wind up $700 and up.

This hybrid boot puts the best features of serious outdoorsman footwear on an ever so slightly more low key design so that it can be worn in the city or the woods.

The Ordering Process

You order from Thursday Boot Company and it arrives at your door within three days. Shipping’s free and so are exchanges if they don’t fit right.

The worst thing about Nicks Boots isn’t the price, it’s the wait. They make your boots to order and while this does helps keep the price down and it helps with sustainability and waste and so on, you will wait 18 to 35 weeks on average for Nicks boots. That’s 4 to 8 months.

And if you get the wrong size, there’s no easy same-week swap.

Those two differences — the price and the wait — are what will cinch this for most guys.

Wrapping Up

So, look man, that’s about everything. Nicks are made in America and have way more widths and customization options, but just about everything else is the same or better with the Challenger and above all, with Thursday, you don’t have to wait 6 months for your god damn boots.